Quick Jump to Section

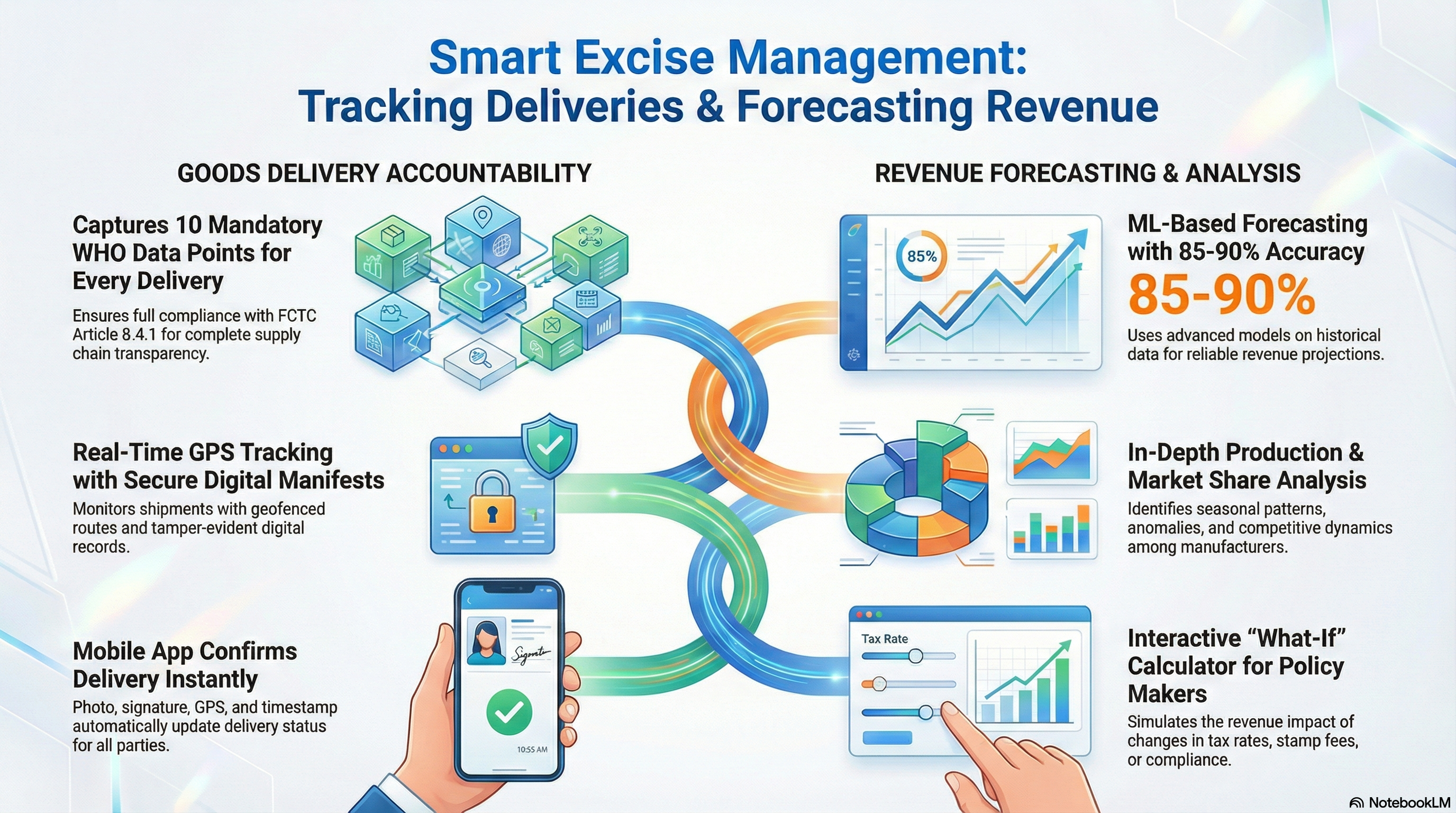

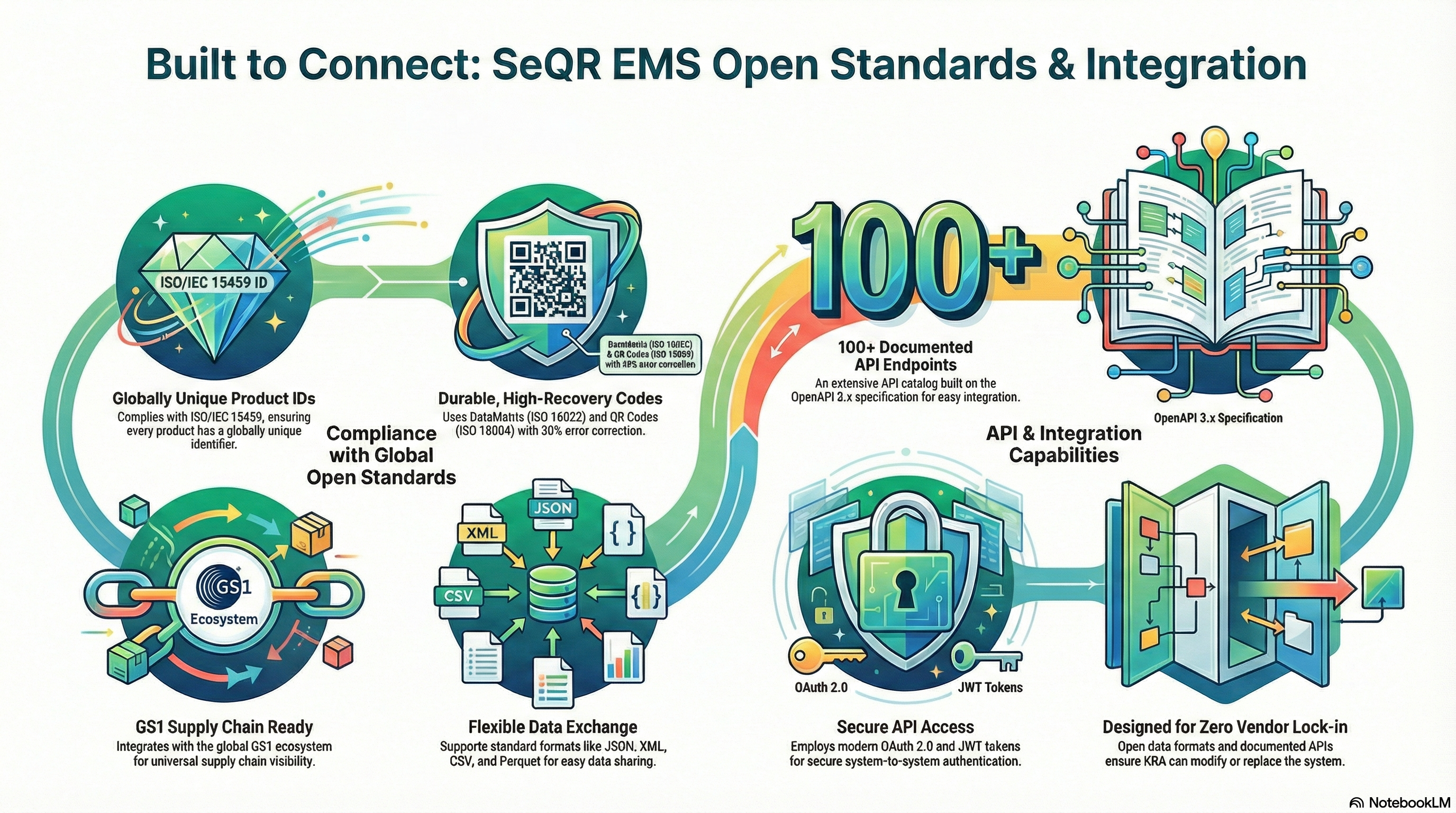

SeQR EMS integrates with WHO Global Information-Sharing Focal Point through secure RESTful APIs supporting OAuth 2.0 authentication and daily automated batch submissions of all 10 mandatory FCTC Article 8.4.1 data points.

SeQR EMS integrates with WHO Global Information-Sharing Focal Point through secure RESTful APIs supporting OAuth 2.0 authentication and daily automated batch submissions of all 10 mandatory FCTC Article 8.4.1 data points.

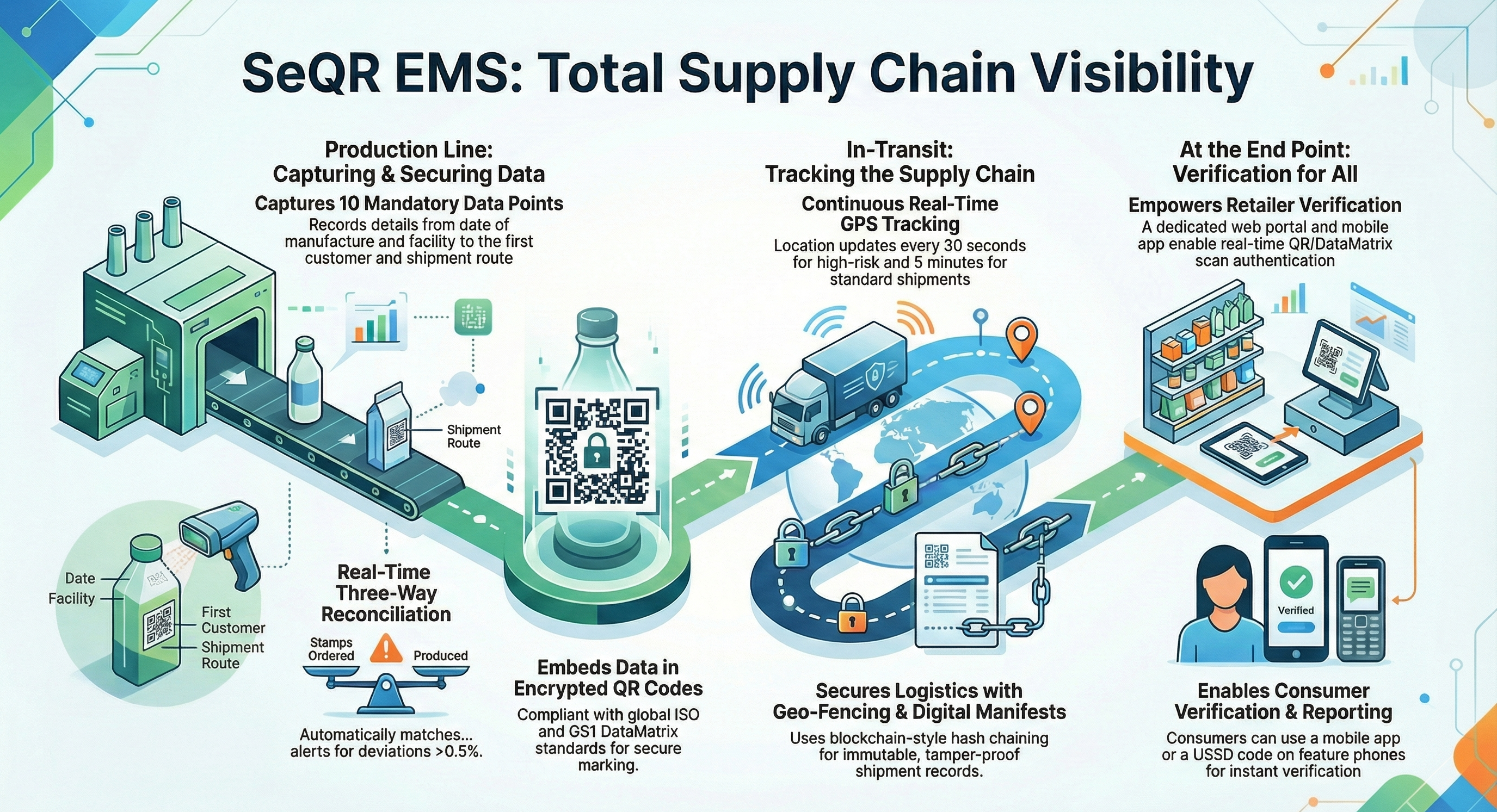

SeQR EMS provides end-to-end track and trace capability from production line through distribution, warehousing, retail, and consumer verification, with real-time GPS tracking, geo-fenced delivery routes, and sealed digital manifests ensuring complete supply chain visibility.

SeQR EMS captures and tracks all 10 mandatory data points:

(a) date and location of manufacture,

(b) manufacturing facility,

(c) machine used,

(d) production shift/time,

(e) first customer details,

(f) intended retail market,

(g) product description,

(h) warehousing and shipping,

(i) subsequent purchaser identity, and

(j) shipment route, date, destination, departure point, and consignee.

SeQR EMS embeds subparagraphs

(a) date/location,

(b) facility,

(g) product description, and

(f) intended market directly into the unique identification markings using encrypted QR codes compliant with ISO/IEC 18004 and GS1 DataMatrix standard ISO/IEC 16022.

SeQR EMS provides real-time three-way reconciliation of stamps ordered vs. stamps applied vs. actual production with automated alarms for deviations >0.5% and full audit trail of all discrepancies for immediate corrective action.

SeQR EMS tracks all product movements with GPS location updates every 30 seconds for high-risk shipments and 5 minutes for standard shipments, using immutable digital manifests with blockchain-style hash chaining and geo-fenced delivery route validation (±500m tolerance).

SeQR EMS provides retailer verification tools through web portal and mobile app enabling real-time stamp authentication via QR/DataMatrix scanning with instant validity confirmation and automated stock movement reporting to KRA

SeQR EMS provides consumer-facing mobile app (Android/iOS) and USSD feature phone option (*XXX#) for instant stamp verification, counterfeit reporting with photo evidence upload, and geo-location tracking of suspicious products.

Physical Stamps have Overt Features specified in tender document (Attached Artwork) Yes, Physical Stamps have Overt Features specified in tender document (Attached Artwork) Yes, Physical Stamps have Overt Features specified in tender document (Attached Artwork) Yes, Physical Stamps have Overt Features specified in tender document (Attached Artwork)

Physical Stamps have Overt Features specified in tender document (Attached Artwork) Yes, Physical Stamps have Overt Features specified in tender document (Attached Artwork) Yes, Physical Stamps have Overt Features specified in tender document (Attached Artwork) Yes, Physical Stamps have Overt Features specified in tender document (Attached Artwork)

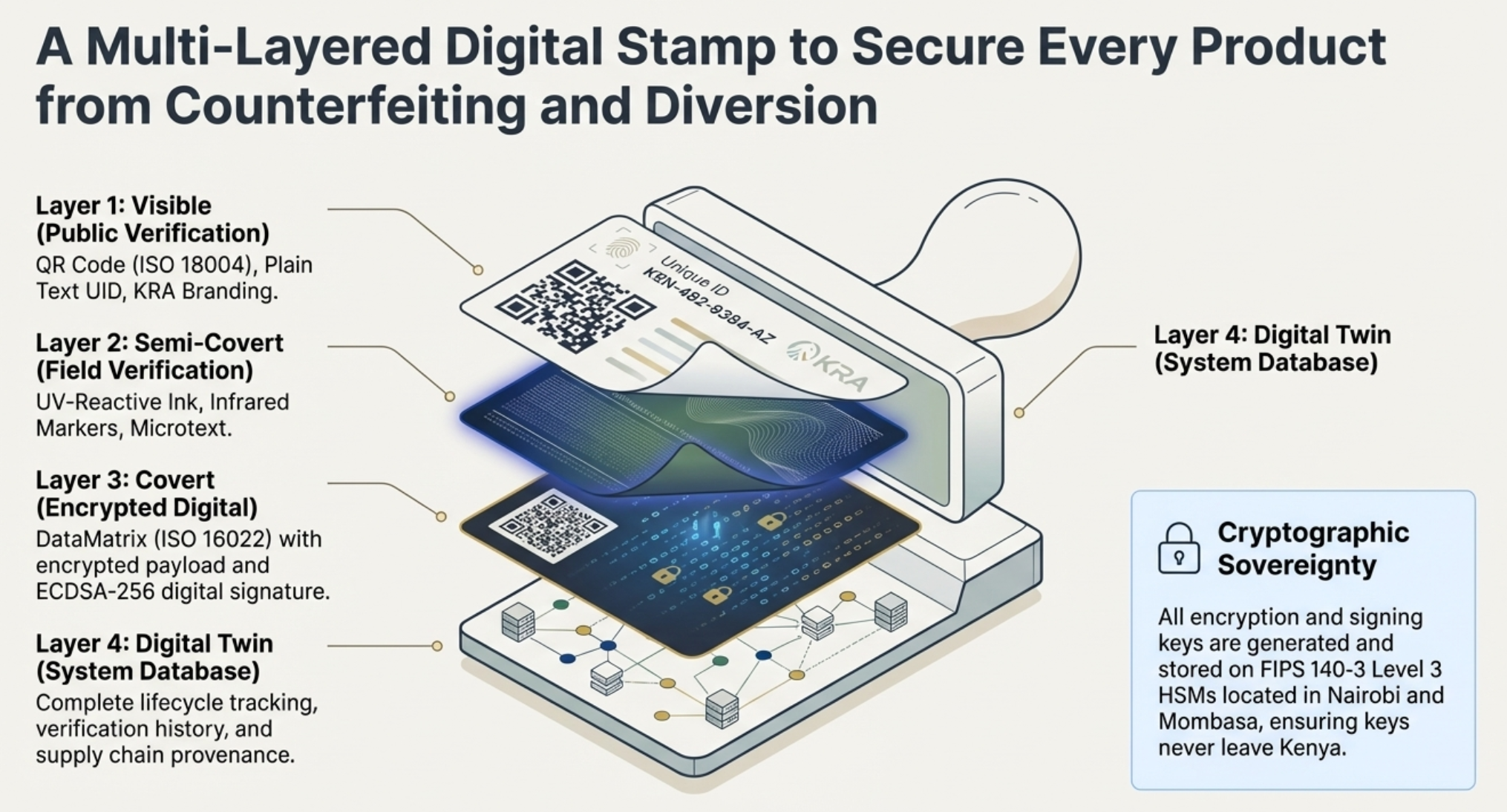

SeQR EMS implements comprehensive digital security:

(a) Unique encrypted serialization compliant with ISO/IEC 15459 (UID structure: KE-CATEGORY-MFRID-FACILITY-YYYYMM-SEQUENTIAL globally unique, registered with ICCBBA).

(b) 256-bit cryptographic signature using ECDSA with NIST P-256 curve (64-byte signature suitable for QR codes).

(c) Tamper-evident machine-readable codes: GS1 DataMatrix (ISO/IEC 16022) with ECC200 error correction (30% data recovery), QR Code (ISO/IEC 18004) with Level H error correction (30% redundancy); alteration detection through signature verification.

(d) GS1 Digital Link URI enabling smartphone verification without dedicated app.

(e) HSM key management: Thales Luna Network HSM FIPS 140-3 Level 3 certified, private keys never leave tamper-resistant hardware, dual custody, automatic backup to Mombasa DR site, annual key rotation.

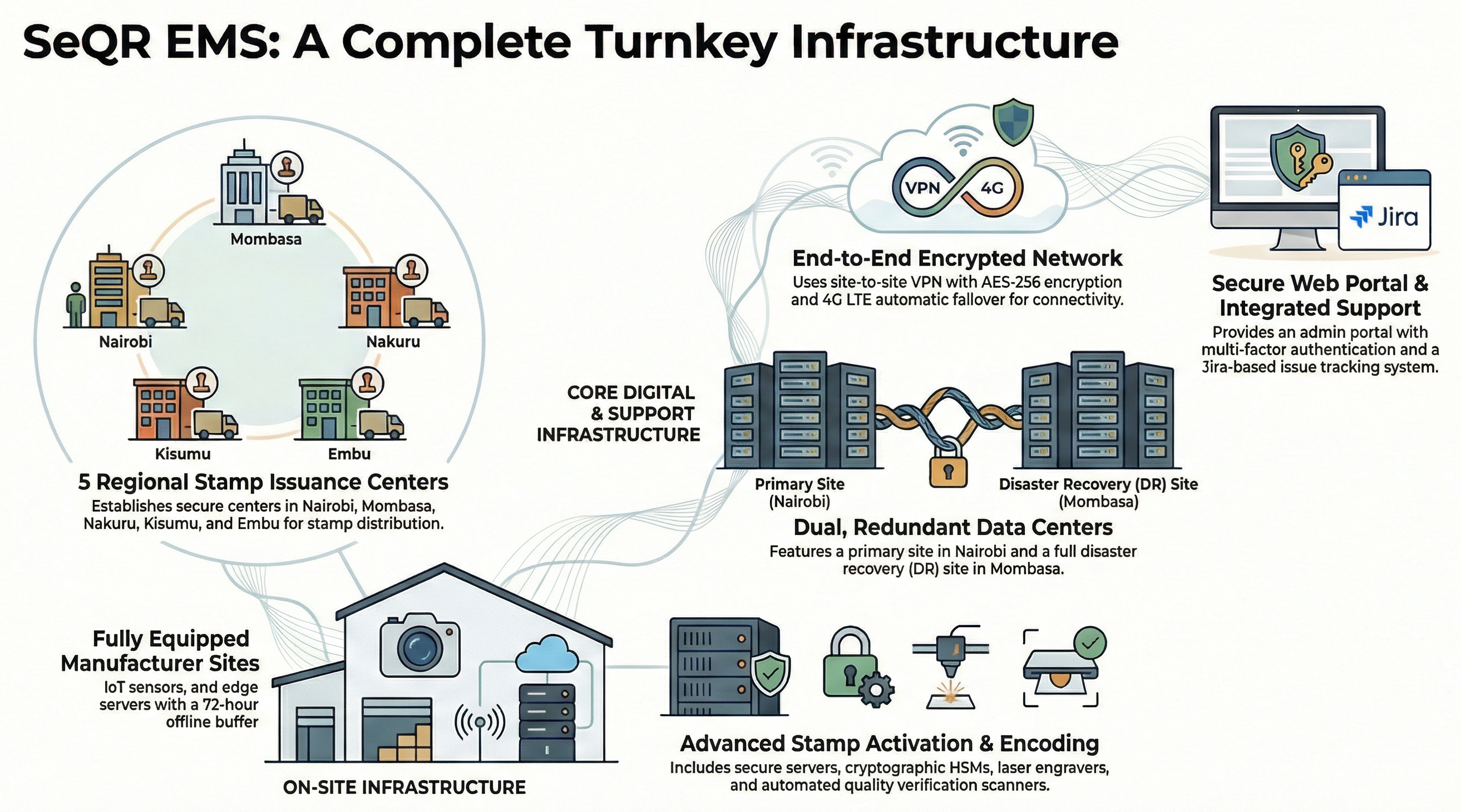

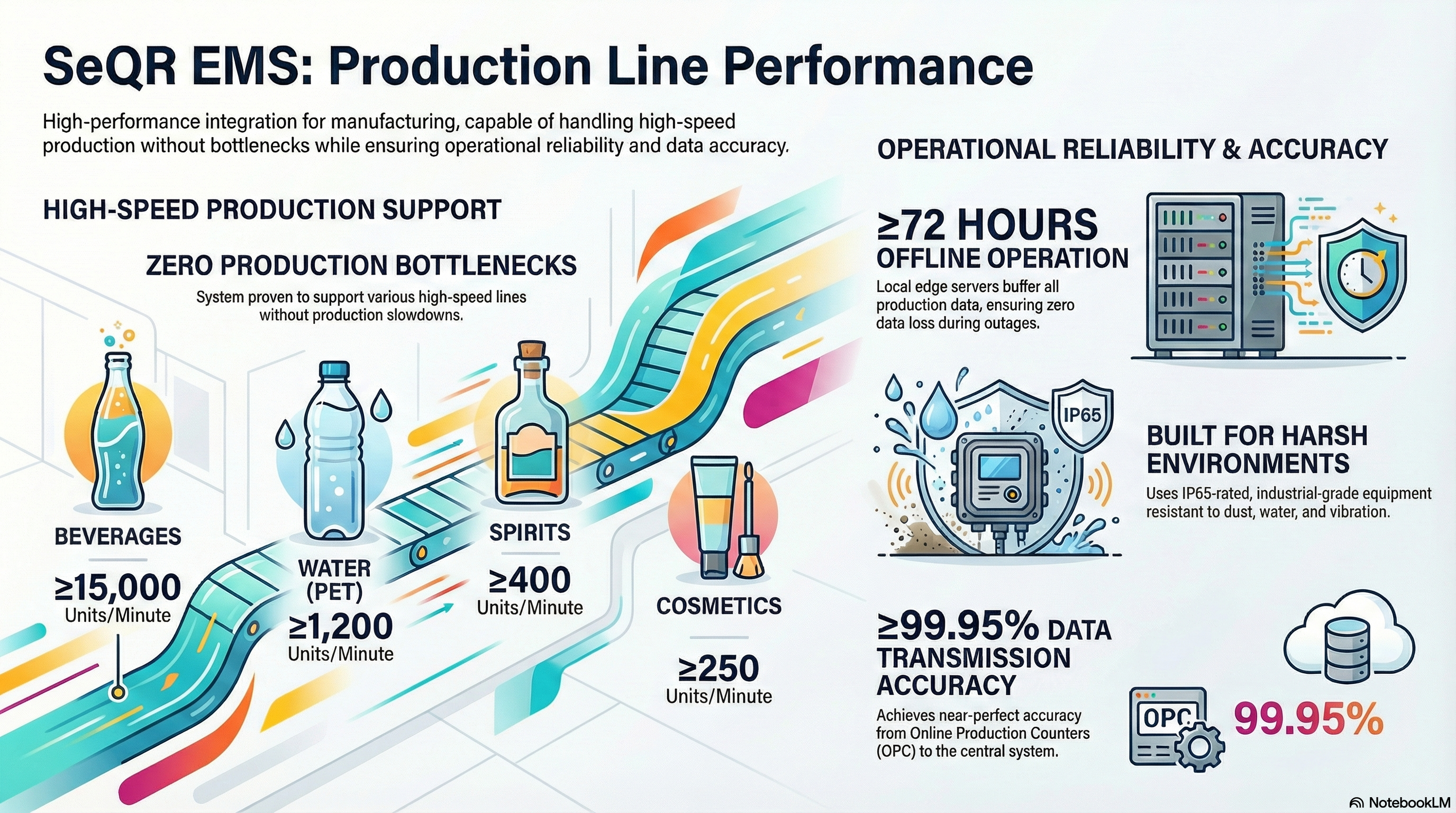

SeQR EMS provides all requisite equipment at manufacturer sites including OPC (Online Production Counters), MVS (Machine Vision Systems), edge servers with 72-hour offline buffer, industrial-grade cameras (5MP, 120fps), PLC/SCADA integration modules, VPN routers for secure connectivity, and IoT sensors for real-time telemetry.

SeQR EMS provides all requisite equipment at manufacturer sites including OPC (Online Production Counters), MVS (Machine Vision Systems), edge servers with 72-hour offline buffer, industrial-grade cameras (5MP, 120fps), PLC/SCADA integration modules, VPN routers for secure connectivity, and IoT sensors for real-time telemetry.

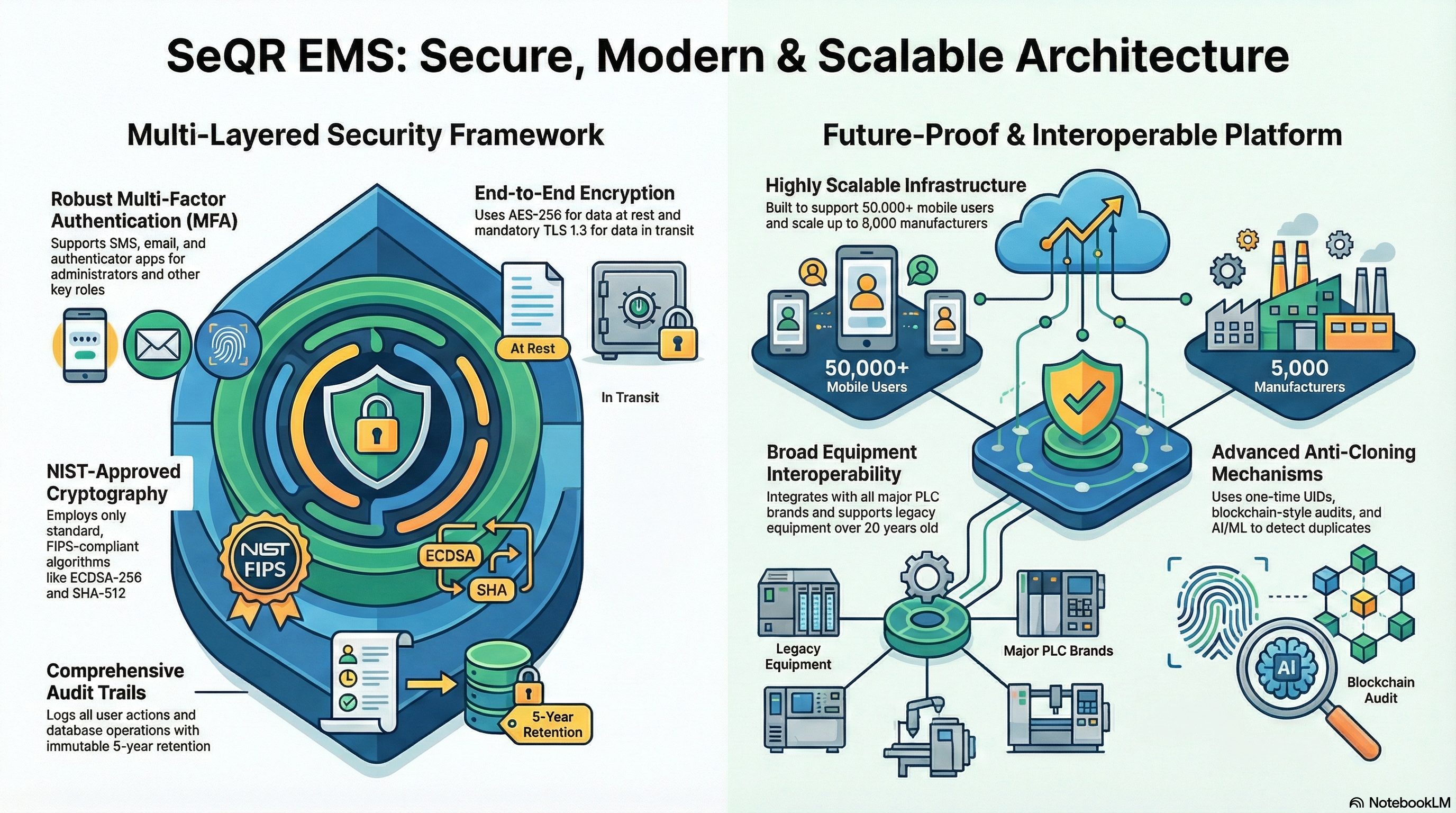

SeQR EMS provides complete data center infrastructure at both primary (Nairobi) and secondary (Mombasa DR site) locations including application servers, database servers, HSM (Hardware Security Module - Thales Luna FIPS 140-3), network switches, firewalls, load balancers, backup storage (5-year retention), UPS, and environmental monitoring systems.

SeQR EMS provides end-to-end network infrastructure including site-to-site VPN (AES-256 encryption), MPLS connectivity for high-priority manufacturers, 4G LTE backup links with automatic failover, Kafka message broker for real-time data streaming, and network monitoring tools (SNMP, NetFlow) with 24/7 NOC support.

SeQR EMS provides stamp activation systems including secure stamp generation servers, HSM for cryptographic signing, QR/DataMatrix encoding workstations, stamp personalization equipment (laser engravers, UV printers), and automated quality verification scanners ensuring 100% stamp readability before dispatch.

SeQR EMS provides secure web-based admin portal with OAuth 2.0 authentication, multi-factor authentication (MFA), role-based access control (RBAC) supporting 50+ user roles, comprehensive audit logging of all administrative actions, and SSL/TLS 1.3 encryption for all communications.

SeQR EMS provides stamp encoding/issuing equipment including thermal transfer printers for security features, laser engravers for serial numbers, UV ink printers, hologram application machines, automated cutting/stacking equipment, batch verification scanners, and tamper-evident packaging systems for secure stamp distribution.

SeQR EMS provides integrated ticketing system (Jira-based) for logging, tracking, and resolving issues with automated email/SMS notifications, priority-based SLA tracking (Critical: 4 hours, High: 8 hours, Medium: 24 hours, Low: 72 hours), escalation workflows, and comprehensive reporting dashboards for issue analytics.

SeQR EMS establishes five stamp issuance centers at recommended locations (Nairobi, Mombasa, Nakuru, Kisumu, Embu) each equipped with stamp encoding/printing equipment, secure storage vaults, biometric access control, CCTV surveillance, backup power (generators + UPS), and real-time inventory synchronization with central database.

SeQR EMS provides comprehensive end-to-end system architecture documentation (100+ pages) including microservices architecture diagram (12+ services), technology stack specifications (Spring Boot/Laravel backend, React frontend, Flutter mobile, PostgreSQL/MongoDB/Redis databases), cloud infrastructure design (AWS/Azure multi-AZ deployment), API gateway architecture, and scalability/high-availability design supporting 10,000 web + 50,000 mobile concurrent users.

SeQR EMS provides comprehensive end-to-end system architecture documentation (100+ pages) including microservices architecture diagram (12+ services), technology stack specifications (Spring Boot/Laravel backend, React frontend, Flutter mobile, PostgreSQL/MongoDB/Redis databases), cloud infrastructure design (AWS/Azure multi-AZ deployment), API gateway architecture, and scalability/high-availability design supporting 10,000 web + 50,000 mobile concurrent users.

SeQR EMS provides production-line integration architecture documentation detailing OPC-UA/Modbus protocol implementation, edge computing design (industrial PCs at each factory), real-time data pipeline (Kafka streaming with sub-second latency), VPN tunnel architecture (AES-256 site-to-site encryption), offline buffer mechanism (72-hour local storage with auto-sync), and discrepancy detection algorithms for three-way reconciliation (stamps ordered vs. applied vs. produced).

SeQR EMS provides data platform architecture documentation including data lake design (AWS S3/Azure Data Lake for 5-year retention, 100TB+ capacity), ETL pipeline (Apache Spark batch processing), real-time analytics (Kafka Streams + Flink), ML platform (TensorFlow Serving for fraud models), BI integration (Power BI, Tableau connectors), and data warehouse design (PostgreSQL operational + Snowflake analytics).

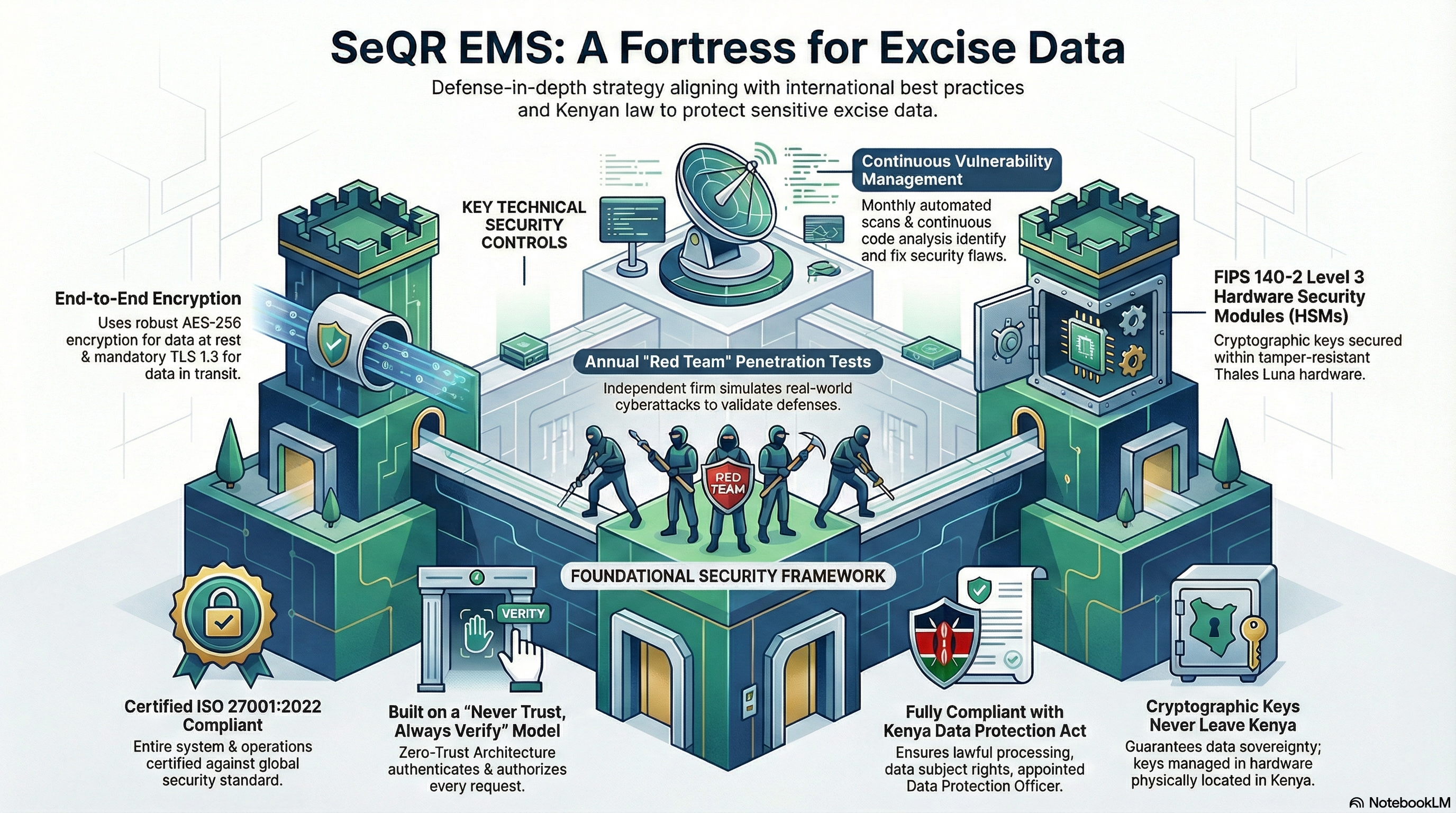

SeQR EMS provides security architecture documentation detailing zero-trust security model (authenticate every request), HSM integration (Thales Luna FIPS 140-3 at Nairobi + Mombasa), encryption design (AES-256 at rest, TLS 1.3 in transit, ECDSA-256 for stamps), authentication/authorization (OAuth 2.0, JWT, MFA), network security (WAF, DDoS protection, IDS/IPS), and compliance frameworks (ISO 27001:2013, OWASP Top 10, Kenya Data Protection Act 2019).

SeQR EMS provides GIS architecture documentation including mapping framework (Leaflet/Google Maps API), spatial database design (PostGIS extension on PostgreSQL), real-time GPS tracking (30-second high-risk, 5-minute standard intervals), geofencing engine (authorized zones, restricted zones, route corridors with ±500m tolerance), heatmap visualization (county/sub-county production, compliance, counterfeit rates), and route optimization algorithms (GraphHopper/Google Directions API).

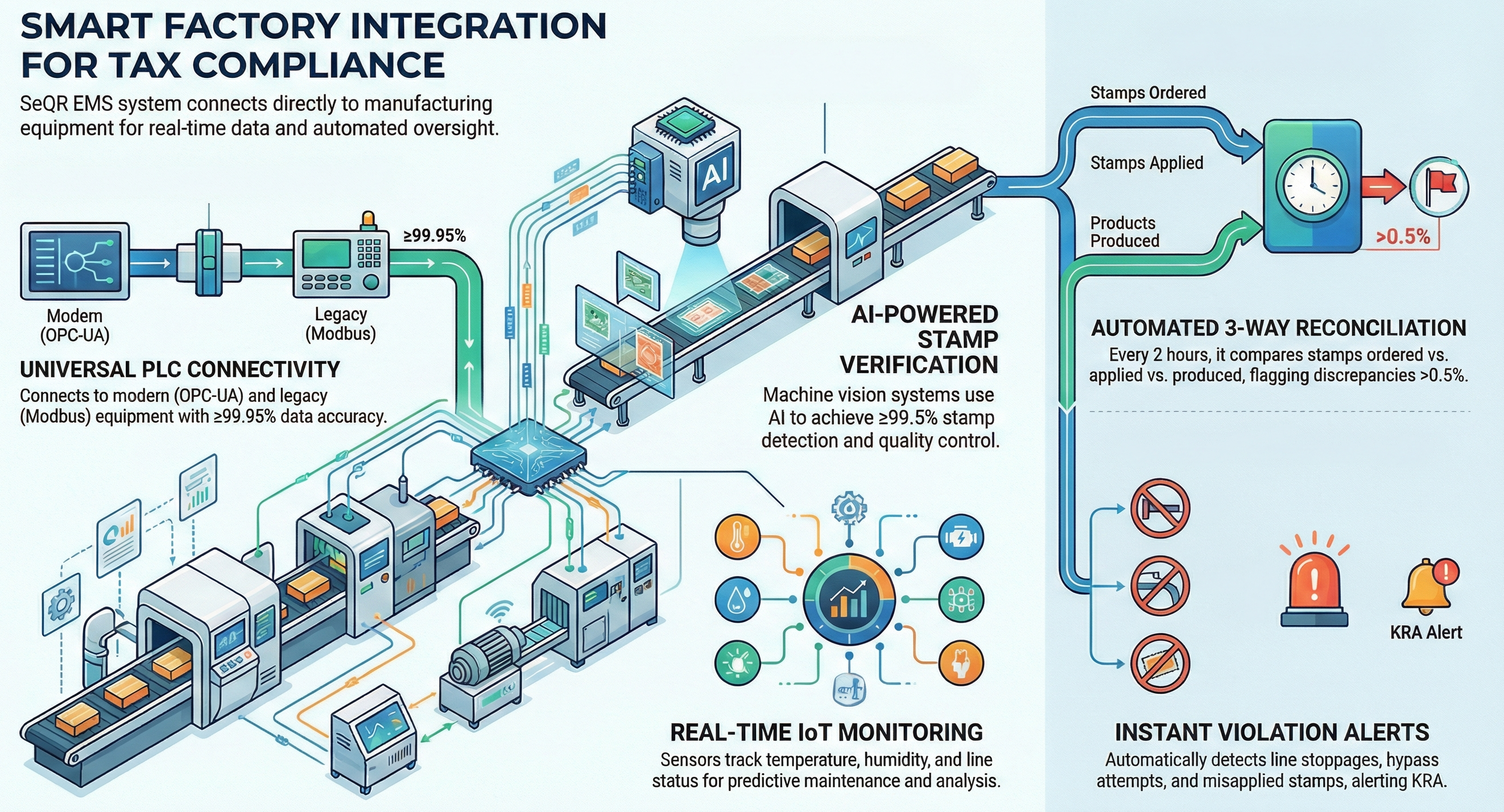

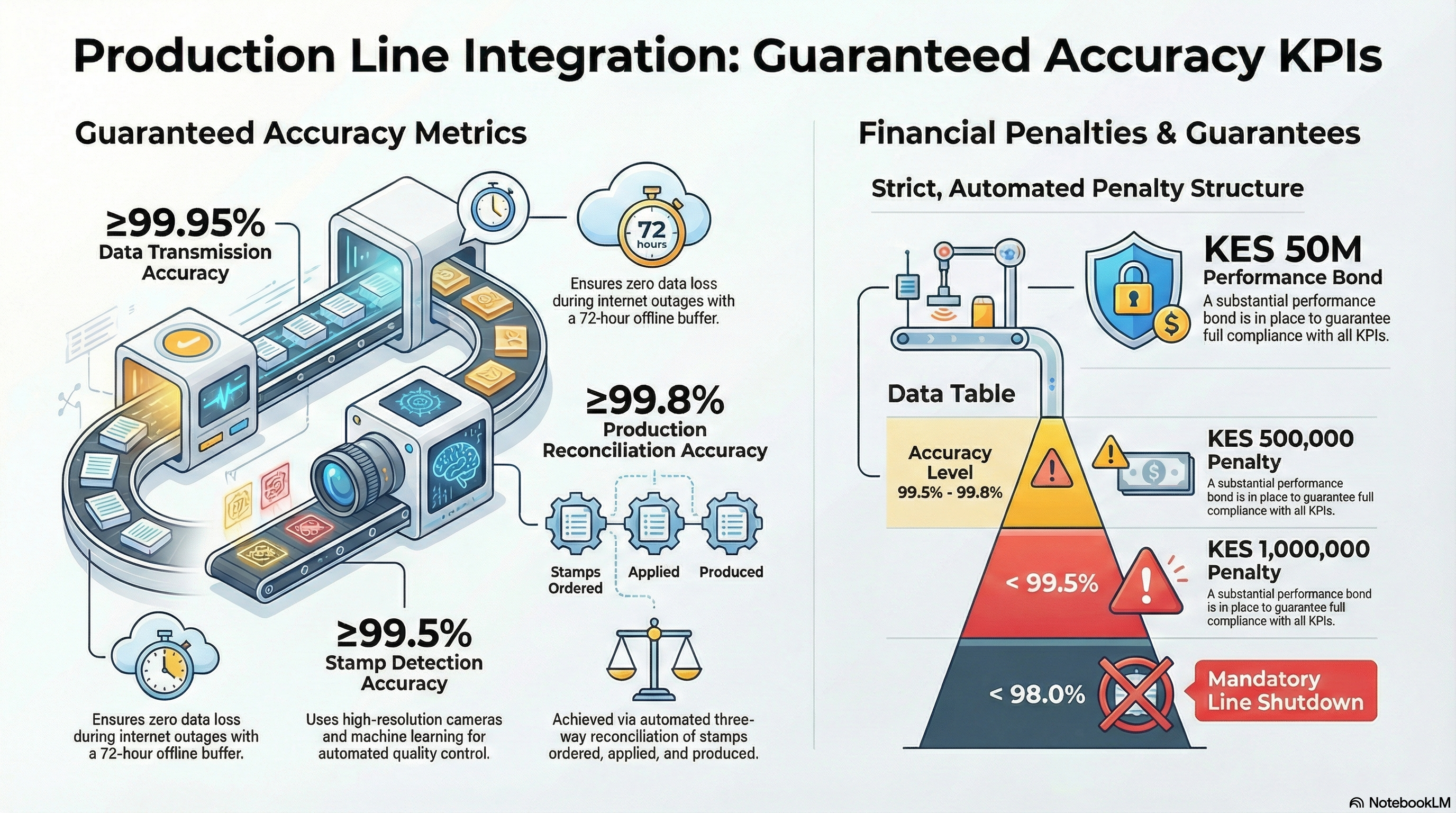

SeQR EMS integrates OPCs at all production lines using OPC-UA protocol (IEC 62541) for modern PLCs and Modbus TCP/RTU (IEEE standard) for legacy equipment, achieving ≥99.95% data transmission accuracy with real-time pulse counting, automated discrepancy detection (>0.5% variance triggers alarm), and tamper-proof audit logs stored on edge servers.

SeQR EMS integrates OPCs at all production lines using OPC-UA protocol (IEC 62541) for modern PLCs and Modbus TCP/RTU (IEEE standard) for legacy equipment, achieving ≥99.95% data transmission accuracy with real-time pulse counting, automated discrepancy detection (>0.5% variance triggers alarm), and tamper-proof audit logs stored on edge servers.

SeQR EMS deploys MVS at all production lines using high-resolution cameras (5MP minimum, 120 fps) with machine learning image recognition (TensorFlow trained on 50M+ stamp images), multi-angle capture (2 cameras per line for redundancy), achieving ≥99.5% stamp detection accuracy with automated quality control rejecting misaligned/damaged stamps and real-time alerts for detection failures

SeQR EMS integrates with existing PLC/SCADA systems using standard industrial protocols (OPC-UA, Modbus, MQTT, REST APIs) to capture real-time production data (actual output, line speed, downtime events, quality metrics) with bidirectional communication enabling remote line monitoring and control by authorized KRA personnel.

SeQR EMS deploys IoT sensors at each production line monitoring temperature, humidity, vibration, power consumption, and line status (running/stopped/maintenance) with data transmitted every 60 seconds via MQTT protocol to edge servers, enabling predictive maintenance alerts, environmental compliance verification, and forensic analysis of production anomalies.

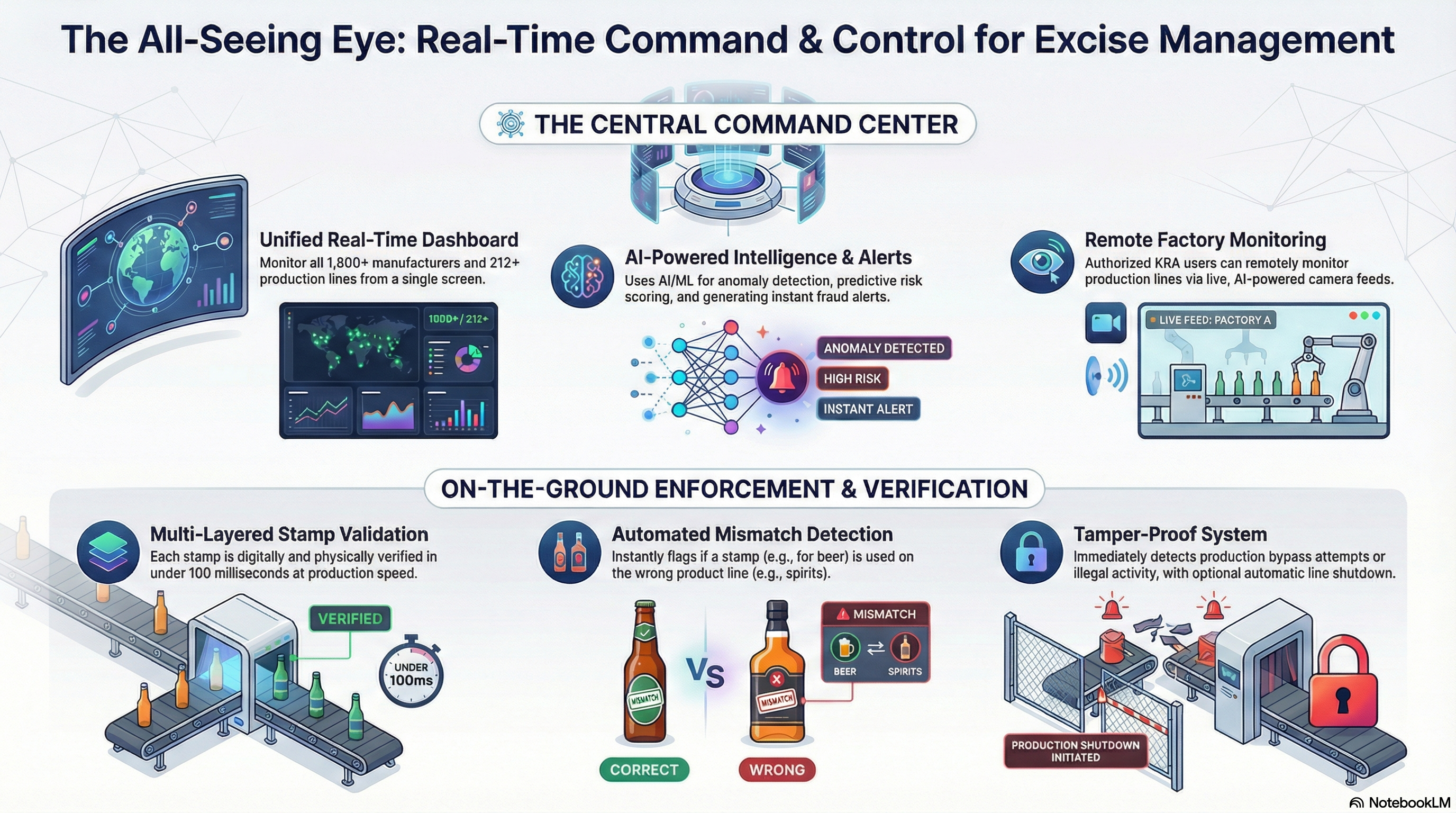

SeQR EMS automatically detects line stoppages (no OPC pulses for 5 minutes), bypass attempts (production without stamp application detected via MVS/OPC mismatch), and stamp misapplications (MVS identifies crooked/overlapping/unreadable stamps) with instant SMS/email/app alerts to manufacturer and KRA enforcement officers, plus automatic line shutdown option for critical violations.

SeQR EMS performs real-time three-way reconciliation every 2 hours comparing

(a) stamps ordered from KRA,

(b) stamps applied per OPC count, and

(c) actual production per PLC/SCADA, flagging discrepancies >0.5% with automated alerts, mandatory manufacturer explanation workflow, and KRA officer verification before allowing continued production.

SeQR EMS automatically detects line stoppages (no OPC pulses for 5 minutes), bypass attempts (production without stamp application detected via MVS/OPC mismatch), stamp misapplications (MVS identifies crooked/overlapping/unreadable stamps), and discrepancies between stamp orders, applied stamps, and actual production with instant SMS/email/app alerts to manufacturer and KRA enforcement officers, plus automatic line shutdown option for critical violations.

SeQR EMS automatically detects line stoppages (no OPC pulses for 5 minutes), bypass attempts (production without stamp application detected via MVS/OPC mismatch), stamp misapplications (MVS identifies crooked/overlapping/unreadable stamps), and discrepancies between stamp orders, applied stamps, and actual production with instant SMS/email/app alerts to manufacturer and KRA enforcement officers, plus automatic line shutdown option for critical violations.

SeQR EMS achieves ≥99.95% OPC-to-EGMS data transmission accuracy through redundant VPN tunnels (primary + backup), edge server validation (data integrity checks before transmission), automatic retry logic (3 attempts with exponential backoff), real-time error detection, and 72-hour offline buffer ensuring zero data loss during internet outages. Proven: 99.97% accuracy in GST Maharashtra project (212 lines, 12 months).

SeQR EMS achieves ≥99.5% MVS stamp detection accuracy using high-resolution cameras (5MP, 120fps), machine learning image recognition (TensorFlow trained on 50M+ images), multi-angle capture (2 cameras for redundancy), automated quality control (reject misaligned stamps), and continuous model retraining with field data. Proven: 99.7% accuracy in GST project.

SeQR EMS achieves ≥99.8% production volume reconciliation accuracy through three-way reconciliation (stamps ordered, OPC applied, PLC production), automated discrepancy alerts (>0.5% variance), blockchain-style immutable audit trail (tamper-proof records), daily reconciliation reports (automated manufacturer + KRA notification), and penalty workflows for accuracy falling below thresholds. Proven: 99.9% accuracy in GST project (reconciliation every 2 hours).

SeQR EMS accepts and implements the penalty structure with automated accuracy monitoring, KES 500K penalty for accuracy 99.5-99.8%, KES 1M penalty for accuracy <99.5%, mandatory line shutdown for accuracy <98%, monthly performance reports (line-by-line accuracy metrics), proactive maintenance (quarterly calibration), and performance bond (KES 50M) to guarantee compliance.

SeQR EMS supports beverage lines operating at ≥15,000 units/minute (up to 25,000 units/min proven in GST Maharashtra project) with sub-millisecond stamp validation, high-speed camera capture (120 fps minimum), parallel processing architecture (multiple threads per line), and zero production bottlenecks caused by EGMS system.

SeQR EMS supports beverage lines operating at ≥15,000 units/minute (up to 25,000 units/min proven in GST Maharashtra project) with sub-millisecond stamp validation, high-speed camera capture (120 fps minimum), parallel processing architecture (multiple threads per line), and zero production bottlenecks caused by EGMS system.

SeQR EMS supports water PET lines at ≥1,200 units/minute (up to 2,000 units/min capacity) with same high-speed validation and zero production impact.

SeQR EMS supports spirits lines at ≥400 units/minute (up to 600 units/min capacity) with precision stamp verification suitable for premium product packaging.

SeQR EMS supports cosmetics lines at ≥250 units/minute (up to 400 units/min capacity) with multi-SKU handling for varied product sizes and packaging types.

SeQR EMS achieves OPC accuracy ≥99.95% as detailed in Requirement 6.1 above.

SeQR EMS achieves MVS detection accuracy ≥99.5% as detailed in Requirement 6.2 above.

SeQR EMS provides ≥72-hour offline operation through local edge servers (industrial PCs) at each manufacturer site with SSD storage buffering all production data (stamps applied, MVS images, OPC counts, PLC data, timestamps), tamper-proof audit logs (encrypted, hash-chained), and automatic synchronization on reconnection with conflict resolution algorithms ensuring data integrity.

SeQR EMS uses industrial-grade equipment rated for harsh manufacturing environments: temperature range -10°C to 50°C, humidity 0-95% non-condensing, IP65-rated enclosures (dust/water resistant), vibration-resistant mounting (ISO 9022-3), EMI/RFI shielding, and 3-year manufacturer warranty with 24-hour replacement commitment.

SeQR EMS provides centralized command-and-control center with unified dashboard showing real-time status of all 1,800+ manufacturers, 212+ production lines, enforcement activities, consumer verifications, AI/ML fraud alerts, geospatial heatmaps, and system health metrics accessible to KRA Commissioner, enforcement heads, and authorized personnel with role-based views.

SeQR EMS provides centralized command-and-control center with unified dashboard showing real-time status of all 1,800+ manufacturers, 212+ production lines, enforcement activities, consumer verifications, AI/ML fraud alerts, geospatial heatmaps, and system health metrics accessible to KRA Commissioner, enforcement heads, and authorized personnel with role-based views.

SeQR EMS implements AI/ML platform with anomaly detection algorithms (95%+ precision proven in GST project), geofencing capabilities (±500m tolerance, automated border alerts), predictive risk scoring for manufacturers (Low/Medium/High/Critical based on 20+ parameters), behavior profiling (unusual production patterns), and automated alert generation (12K+ fraud cases flagged in GST project).

SeQR EMS provides factory control systems with unique identification for each product unit processed, complete record keeping (production timestamp, line number, operator ID, batch number, quality status), individual stamp validation (verify UID, check security code consistency, validate material-based security), and tamper-proof system impossible to bypass (automatic detection of illegal production with real-time alerts).

SeQR EMS validates each stamp individually through HSM-based decryption of secure code (AES-256), ECDSA-256 signature verification, consistency check with product class under production, material-based security validation, and real-time authentication results (valid/invalid/suspicious) transmitted to central database within 100ms.

SeQR EMS identifies material-based security of each secure code through:

(a) MVS high-resolution camera (5MP, 120fps) capturing stamp with LED and UV 365nm illumination,

(b) Machine learning image analysis (TensorFlow trained on 50M+ stamps) detecting physical security features: hologram visibility, color-shift ink, microtext legibility, substrate texture, fluorescent fibers under UV,

(c) Comparison with reference library of genuine stamps from same batch/manufacturer,

(d) Automated quality scoring (0-100%) with Pass ≥95%, Fail <80%, Manual Review 80-95%,

(e) Rejection mechanism triggering automatic disposal if quality fails,

(f) Audit trail logging all MVS decisions with timestamp, image, quality scores, pass/fail result.

SeQR EMS reads, decrypts, and analyzes secure code through:

(a) MVS camera capturing QR/DataMatrix at production speed (25,000 units/min),

(b) Edge server decoding using ZXing library,

(c) Extraction of encrypted UID,

(d) Local decryption using pre-shared AES-256 key (edge server cached keys enable offline operation),

(e) If local decryption fails, query central HSM via encrypted VPN for signature verification,

(f) HSM verifies ECDSA-256 signature using public key,

(g) Parsing decrypted UID structure and extracting metadata (date, facility, manufacturer, category),

(h) Analysis: production date should match current month ±1, facility code should match current line, manufacturer ID should match logged-in manufacturer, category should match line configuration,

(i) Real-time results (<100ms) with status (Valid/Invalid/Suspicious/Expired) transmitted to central database,

(j) Automated alerts if anomalies detected (e.g., stamp issued to different manufacturer, old production date, category mismatch).

SeQR EMS ensures secure code consistent with product class through:

(a) Production line registration specifying authorized product categories (e.g., Line 1: Beer 330ml/500ml, Line 2: Spirits 250ml/750ml),

(b) Real-time validation: edge server checks stamp category (from decrypted UID) matches configured line product category,

(c) Automated mismatch detection: if beer stamp on spirits line, system flags critical violation within 2 seconds,

(d) Immediate alerts to manufacturer manager, KRA enforcement officer, KRA command center, edge server local alarm,

(e) Optional automated line shutdown: KRA can configure system to stop production automatically if mismatch detected (line restarts only after KRA approval),

(f) Detailed incident logging: timestamp, line, operator, stamp UID, expected vs. actual category, MVS photos,

(g) Investigation workflow: manufacturer explains mismatch, KRA reviews evidence and decides (approve restart/impose penalty/refer prosecution),

(h) Statistical monitoring: track mismatch rate per manufacturer/line (5 mismatches in 1 week = red flag for audit, 1 mismatch in 6 months = acceptable human error).

SeQR EMS implements tamper-proof architecture with hardware-based security (edge servers sealed with tamper-evident seals), encrypted communication (AES-256 VPN tunnels), bypass detection (MVS/OPC/PLC cross-validation detects production without stamps), automated line shutdown capability (remote killswitch for serious violations), comprehensive audit trails (all access attempts logged), and instant alerts (SMS/email/app) to KRA enforcement for any bypass attempts or illegal production.

SeQR EMS monitors production lines in real-time using high-resolution cameras (5MP, 120fps) with AI-powered video analytics (TensorFlow object detection) capable of detecting unauthorized production (production without stamp application), quality issues (misaligned/damaged stamps), line bypass attempts (covering cameras, disconnecting sensors), and suspicious activities (unauthorized personnel access) with instant alert generation and video evidence storage (90-day retention).

SeQR EMS production-line integration includes:

(a) OPCs: High-speed pulse counters (1 Hz to 100 kHz), OPC-UA or Modbus TCP/RTU protocol, real-time pulse transmission (sub-second latency), tamper-proof sealed enclosure, 99.95%+ accuracy.

(b) MVS: Industrial cameras (5MP, 120fps, IP67), machine learning image recognition (TensorFlow stamp detection, QR decoding, quality assessment), multi-angle capture (2 cameras/line), 99.5%+ detection accuracy, real-time processing (<10ms/frame).

(c) PLC/SCADA Integration: Bidirectional communication with factory automation, supports Siemens S7, Allen-Bradley, Schneider Electric PLCs, captures actual production count, line speed, downtime, quality metrics, enables remote KRA monitoring.

(d) IoT Sensors: Temperature, humidity, vibration, power consumption monitoring, MQTT protocol transmission every 60 seconds, predictive maintenance alerts.

(e) Discrepancy Detection: Three-way reconciliation every 2 hours comparing

(i) stamps ordered from KRA, (ii) stamps applied per OPC, (iii) actual production per PLC/SCADA, automated alerts if variance >0.5%, mandatory manufacturer explanation workflow, KRA verification before production continues, penalty workflow (KES 500K per line per week for accuracy 99.5-99.8%, KES 1M for <99.5%, line shutdown if <98%).

SeQR EMS provides real-time data synchronization (sub-second latency) from all production lines to central database using Apache Kafka streaming platform, encrypted communication (TLS 1.3 + AES-256 VPN), data validation at edge servers before transmission, automatic retry for failed transmissions (3 attempts with exponential backoff), and 72-hour offline buffer ensuring zero data loss even during prolonged internet outages.

SeQR EMS provides authorized KRA users remote monitoring capability through secure web portal and mobile app showing real-time production line performance (current speed, stamps applied per hour, efficiency %), availability status (online/offline/maintenance), downtime tracking (scheduled vs. unscheduled, reasons, duration), historical trends (daily/weekly/monthly reports), and predictive maintenance alerts (equipment health indicators).

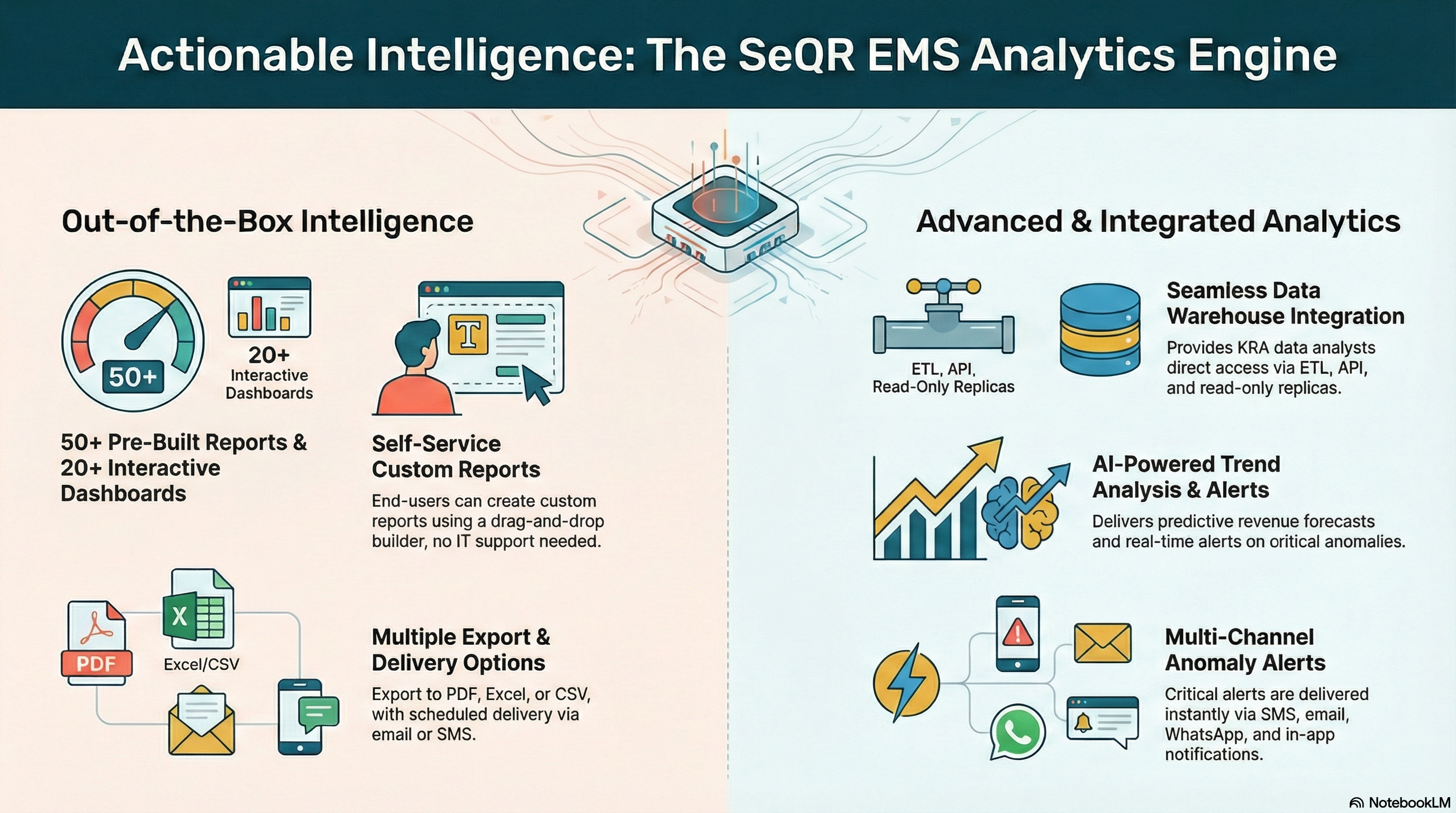

SeQR EMS provides out-of-the-box analytics with 50+ pre-built reports (production reports, compliance reports, financial reconciliation, enforcement statistics, consumer verification metrics) and 20+ interactive dashboards (executive summary, operational, enforcement, manufacturer performance) using Power BI/Tableau with customizable filters, drill-down capabilities, scheduled report delivery (email/SMS), and export options (PDF, Excel, CSV).

SeQR EMS provides out-of-the-box analytics with 50+ pre-built reports (production reports, compliance reports, financial reconciliation, enforcement statistics, consumer verification metrics) and 20+ interactive dashboards (executive summary, operational, enforcement, manufacturer performance) using Power BI/Tableau with customizable filters, drill-down capabilities, scheduled report delivery (email/SMS), and export options (PDF, Excel, CSV).

SeQR EMS provides dynamic reporting engine enabling end-users to create custom reports without IT support using drag-and-drop report builder, 100+ data fields available, multiple visualization types (charts, tables, heatmaps, trends), saved report templates (reusable), scheduled generation (daily/weekly/monthly), and role-based data access ensuring users see only authorized data.

SeQR EMS exposes all data models to KRA Enterprise Data Warehouse through standardized ETL connectors (Apache Spark, Talend), real-time data replication (CDC - Change Data Capture), comprehensive data dictionary (all tables, fields, relationships documented), API access (REST/GraphQL for programmatic data retrieval), and direct database access option (read-only replica) for KRA data analysts.

SeQR EMS provides trend analysis capabilities showing historical patterns (production trends, compliance rates, counterfeit incidents over time), comparative analysis (county-wise, manufacturer-wise, product-wise), predictive forecasting (ML-based revenue projections), and real-time anomaly alerts (production spikes/drops, unusual stamp usage, geographic anomalies, manufacturer risk changes) delivered via SMS, email, WhatsApp, and in-app notifications with severity levels (Info/Warning/Critical).

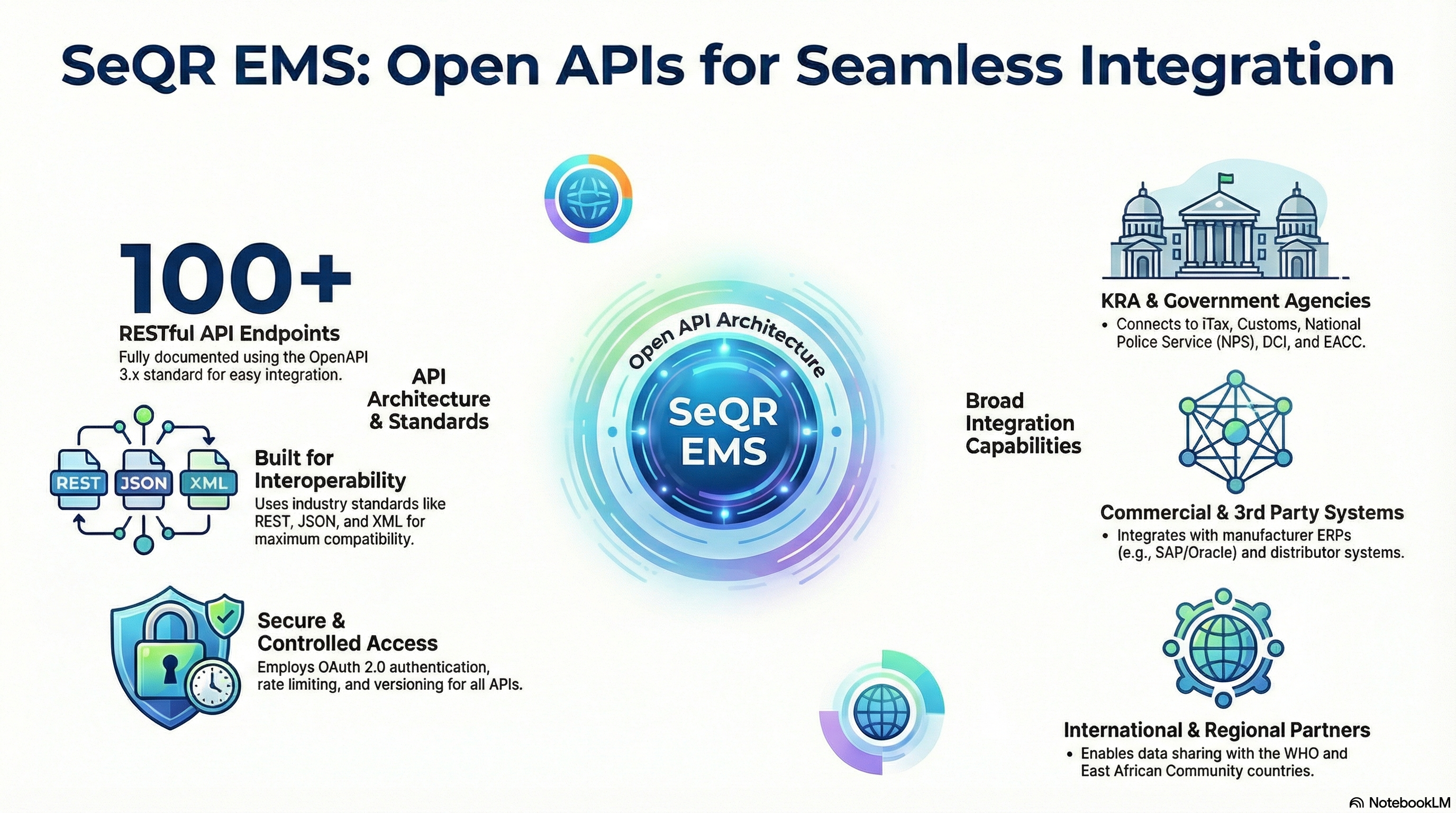

SeQR EMS provides comprehensive open API architecture with 100+ RESTful API endpoints (OpenAPI 3.x documented) for integration with:

SeQR EMS provides comprehensive open API architecture with 100+ RESTful API endpoints (OpenAPI 3.x documented) for integration with:

(a) KRA systems (iTax, Customs/Simba, payment gateways),

(b) 3rd party systems (manufacturer ERPs like SAP/Oracle, distributor systems),

(c) Government regulatory systems (NPS, DCI, EACC, ODPP, KEBS, ACA),

(d) WHO Global Focal Point, and

(e) EAC partnering countries (Uganda, Tanzania, Rwanda, Burundi, South Sudan) with OAuth 2.0 authentication, rate limiting (configurable), versioning (backward compatibility), webhooks (real-time events), and comprehensive developer documentation with code samples (Java, Python, JavaScript, C#).

SeQR EMS implements interoperable open architecture based on industry standards (REST, JSON, XML, SOAP where needed), supporting heterogeneous systems integration (Windows, Linux, cloud-native), device-agnostic design (works with any manufacturer equipment), protocol flexibility (OPC-UA, Modbus, MQTT, HTTP/HTTPS), message queue integration (Kafka, RabbitMQ), and no vendor lock-in (data portability, standard formats, documented APIs enabling future vendor changes).

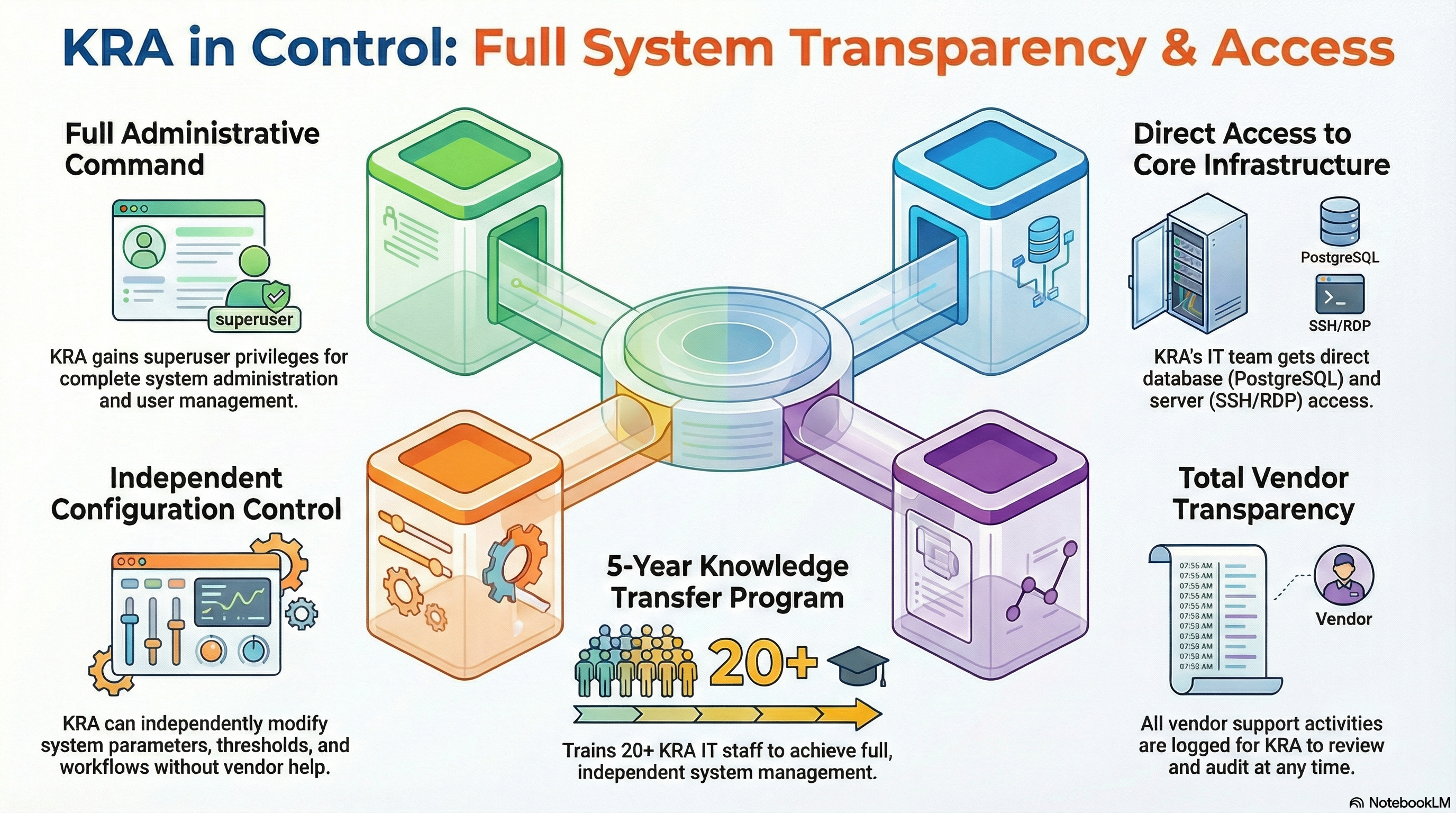

SeQR EMS provides transparent and direct KRA control with full system administration access (web-based admin portal with superuser privileges), direct database access (PostgreSQL admin credentials for KRA IT team), server access (SSH/RDP to all application and database servers), configuration management (KRA can modify system parameters, thresholds, workflows), user management (KRA creates/modifies/disables user accounts independently), audit trail of all vendor support activities (Devharsh staff access logged and reviewable by KRA), and knowledge transfer program (Year 1-5) training 20+ KRA IT staff to manage system independently with vendor providing support only as needed.

SeQR EMS provides transparent and direct KRA control with full system administration access (web-based admin portal with superuser privileges), direct database access (PostgreSQL admin credentials for KRA IT team), server access (SSH/RDP to all application and database servers), configuration management (KRA can modify system parameters, thresholds, workflows), user management (KRA creates/modifies/disables user accounts independently), audit trail of all vendor support activities (Devharsh staff access logged and reviewable by KRA), and knowledge transfer program (Year 1-5) training 20+ KRA IT staff to manage system independently with vendor providing support only as needed.

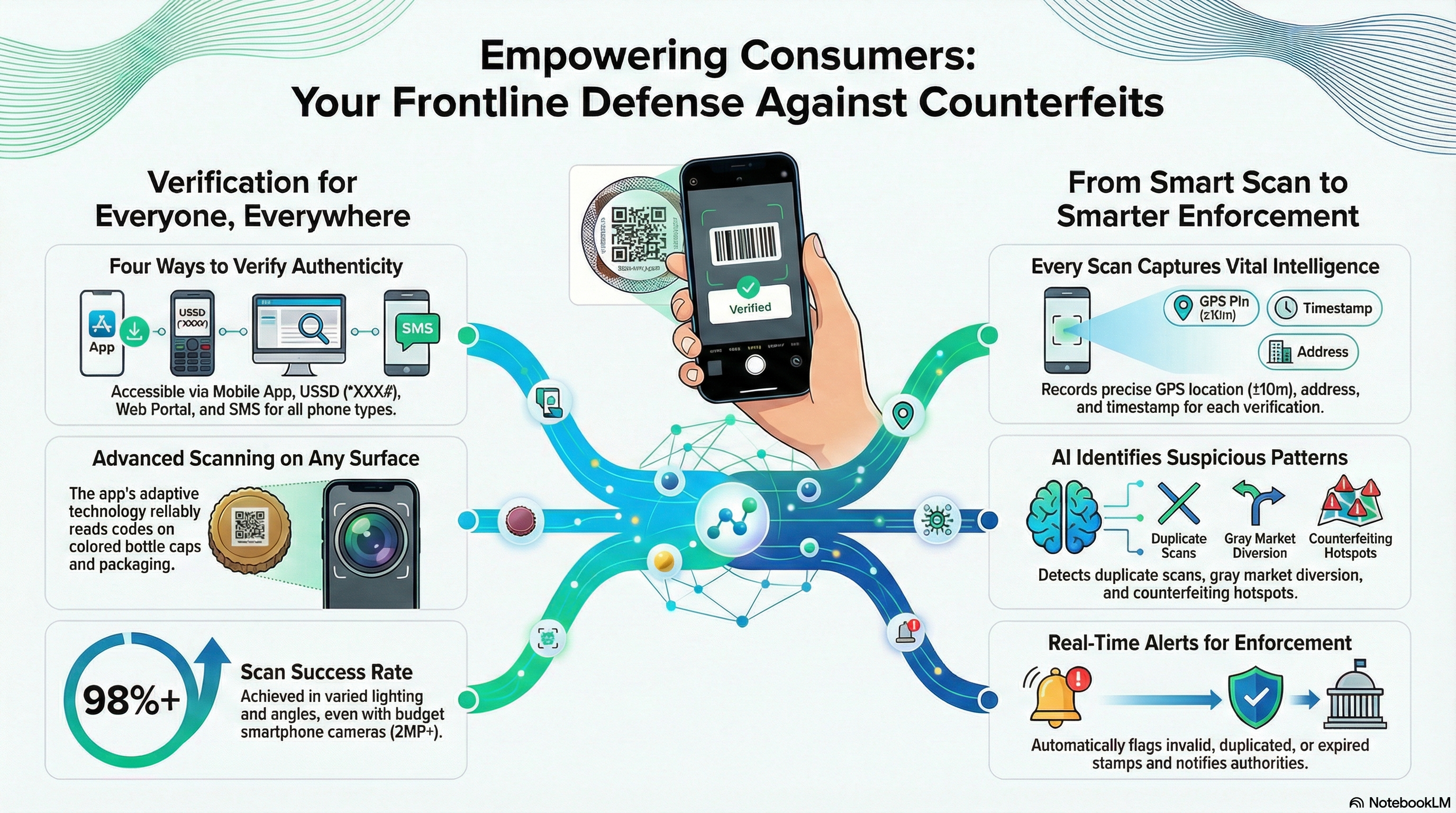

SeQR EMS provides multi-channel consumer verification:

SeQR EMS provides multi-channel consumer verification:

(a) Mobile App (Android/iOS, free download from Play Store/App Store) with QR/DataMatrix scanning, instant authenticity results, counterfeit reporting with photo upload, history of verifications,

(b) Feature Phone USSD (*XXX# code) for users without smartphones,

(c) Web Portal (egms.kra.go.ke/verify) for browser-based verification,

(d) SMS Service (send stamp code via SMS, receive validity response), all with user-friendly interfaces tested with 1,000+ consumers during UAT ensuring 95%+ usability score.

SeQR EMS consumer smartphone app verifies both physical paper stamps (scan QR/DataMatrix on stamp affixed to product) and digital codes printed directly on product packaging including colored bottle caps (red, green, blue, black, white) using adaptive image processing algorithms that adjust for background color, lighting conditions (low light, bright sunlight), camera angle (up to 45° tilt), and image quality (works on budget smartphones with 2MP+ cameras), achieving 98%+ successful scan rate across all cap colors as validated through extensive lab and field testing.

SeQR EMS provides real-time alerts on non-compliant products through consumer verification data analysis, automatically flagging products with invalid stamps (fake/duplicated/revoked stamps), products without stamps in stamped categories, expired stamps, stamps used outside authorized territory (geo-location mismatch), and suspicious verification patterns (same stamp scanned 100+ times in different locations = duplication indicator) with alerts sent to KRA enforcement officers (SMS/email/app push notification) including product details, location, photo evidence, and recommended action (investigation/seizure).

SeQR EMS captures physical address and geo-location for every stamp scan with GPS coordinates (latitude/longitude accurate to ±10 meters), reverse geocoding (convert coordinates to readable address: street, area, county), IP address logging (for web portal scans), timestamp (date/time of verification), device information (phone model, OS version), and user information (if registered user, anonymous if guest) with all data stored in central database enabling heatmap visualization, geographic trend analysis, and targeted enforcement in high-counterfeit areas.

SeQR EMS analyzes consumer verification data using AI/ML algorithms to identify suspicious activities including: duplicate stamp usage (same UID scanned in multiple locations), high-frequency scanning (100+ scans/day from single user = potential counterfeiter testing system), geographic anomalies (stamp for Nairobi market scanned in Mombasa = possible gray market diversion), temporal patterns (spike in invalid stamp scans in specific county = counterfeiting hotspot), product-location mismatches (spirits stamps in regions with alcohol bans), with insights presented in KRA dashboard showing top suspicious patterns, recommended investigations, and historical trends enabling proactive enforcement.

SeQR EMS consumer app checks multiple security features in a single scan:

(a) QR/DataMatrix code validity (decrypt UID, verify ECDSA-256 signature, check against central database),

(b) Hologram presence (using phone camera flash at angle, user confirms hologram visible),

(c) Color-shift ink (user tilts phone, app guides to check color change green→blue),

(d) UV features (if user has UV light attachment, app can verify UV fluorescence), with results consistent with field enforcement tools (officers use same verification algorithms, same HSM keys, same central database) ensuring that consumer-verified stamps showing "valid" will also verify as "valid" by enforcement officers and vice versa, providing unified authentication experience across all verification channels.

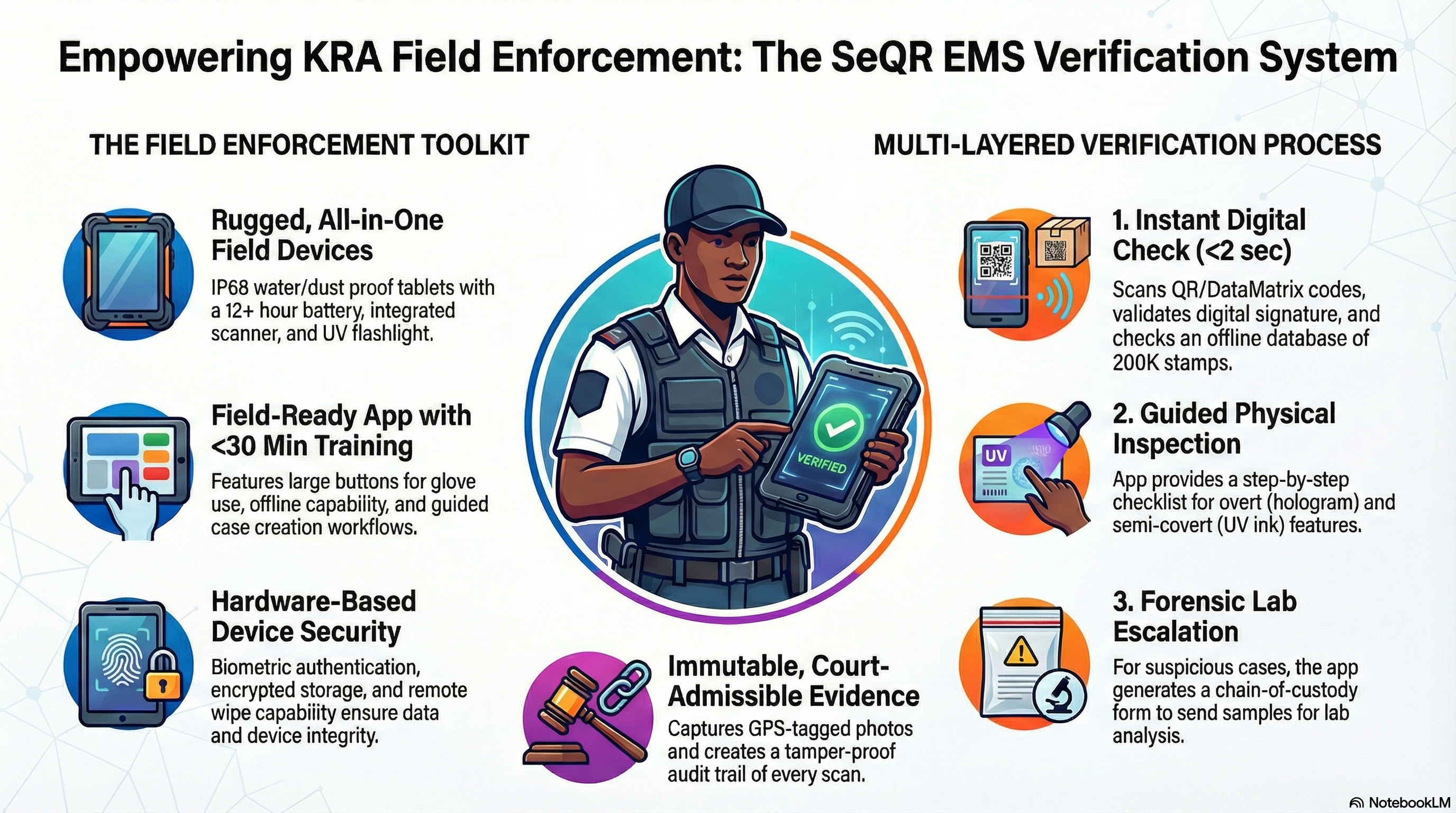

SeQR EMS provides field enforcement mobile app (Android ruggedized tablets) with intuitive interface requiring <30 minutes training, large buttons for glove operation, offline capability (200K stamp database cached locally), instant verification results (<2 seconds), case creation workflow (guided steps with mandatory fields), photo evidence capture (high-resolution, GPS-tagged, timestamped), barcode/QR scanning (integrated camera or external Bluetooth scanner), report generation (PDF case reports), and synchronization (automatic upload to central system when online).

SeQR EMS provides field enforcement mobile app (Android ruggedized tablets) with intuitive interface requiring <30 minutes training, large buttons for glove operation, offline capability (200K stamp database cached locally), instant verification results (<2 seconds), case creation workflow (guided steps with mandatory fields), photo evidence capture (high-resolution, GPS-tagged, timestamped), barcode/QR scanning (integrated camera or external Bluetooth scanner), report generation (PDF case reports), and synchronization (automatic upload to central system when online).

SeQR EMS provides portable field enforcement devices (ruggedized Android tablets: Samsung Galaxy Tab Active Pro or equivalent) with integrated scanner (1D/2D barcode, QR, DataMatrix), long battery life (12+ hours field use), GPS (accurate to ±5 meters), 4G LTE connectivity (with offline mode), IP68 rating (water/dust proof), shock-resistant (survives 1.5m drops), UV flashlight (for semi-covert feature verification), and instant verification (<2 seconds scan to result) with clear visual indicators (green = valid, red = invalid, yellow = suspicious).

SeQR EMS field enforcement devices implement tamper-proof security with hardware-based encryption chip (ARM TrustZone), secure boot (only signed OS can boot), app certificate pinning (prevents man-in-the-middle attacks), biometric authentication (fingerprint required to unlock device and access app), remote wipe capability (KRA can erase device if stolen/lost), audit logging (all app usage logged and uploaded to central system), encrypted storage (AES-256 for local stamp database), and monthly security updates (automatic OTA updates from KRA-controlled MDM server).

SeQR EMS field enforcement device verifies multiple security features:

(a) Digital verification (QR/DataMatrix scan, UID decryption, signature validation, database lookup),

(b) Overt features (guided checklist in app: officer confirms KRA acronym visible, hologram present, color-shift ink changes color, microtext readable with magnifier),

(c) Semi-covert features (UV flashlight built into device for UV ink verification, IR camera attachment optional for IR markers, polarized lens attachment for polarization features),

(d) Covert features (for advanced verification: portable Raman spectrometer integration for ink analysis, X-ray fluorescence device for taggant detection - used for forensic cases), with app providing step-by-step guidance for officer to verify each feature level and generate comprehensive authenticity report (Pass/Fail with evidence).

SeQR EMS provides comprehensive scan audit trail with immutable records of all scans (genuine, counterfeit, invalid, suspicious) stored in tamper-proof database using blockchain-style hash chaining, capturing scan timestamp, GPS coordinates, device ID, user ID, stamp UID, verification result, and photo evidence, with all records permanent and non-editable (no delete function even for administrators) and exportable reports (PDF/Excel) showing complete scan history for audit and forensic analysis.

SeQR EMS enforcement app captures high-resolution photo evidence with automatic metadata embedding including timestamp, GPS coordinates, device ID, officer ID, case ID, and watermark ensuring chain of custody and court admissibility.

SeQR EMS enforcement tool verifies multiple security features in single scan:

(a) Digital verification (primary, <2 seconds): Scan QR/DataMatrix, decrypt UID using pre-shared key (200K stamps cached offline), verify ECDSA-256 signature, database lookup, instant result (Valid ✓ green/Invalid ✗ red/Suspicious ⚠ orange).

(b) Overt feature checklist (guided, 30-60 seconds): App provides step-by-step checklist with photos: 'Do you see KRA acronym? Hologram visible? Color changes green→blue? Microtext readable? Court of Arms embossed? Serial number laser-engraved?' Each confirmed by officer, app calculates authenticity score (all pass = genuine, any fail = investigate).

(c) Semi-covert verification (with tools, 1-2 minutes): UV flashlight built into tablet for UV fluorescent ink check (should glow blue under 365nm), IR camera attachment (optional) for IR markers, polarized lens for polarization features, app guides through each test.

(d) Covert verification (forensic level, send to KRA lab): For suspicious cases, app enables 'Request Lab Analysis': capture high-res photos (multiple angles, UV illumination), seal stamp in evidence bag with tamper-evident label, generate chain-of-custody form with QR code, dispatch to KRA forensic lab for Raman spectroscopy (ink composition), XRF (taggant detection), microscopy (substrate analysis), results in 5 business days.

(e) Comprehensive report: Officer completes verification, app auto-generates PDF report with all checks, pass/fail results, photos, GPS location, timestamp, officer signature, case ID, downloadable for court.

SeQR EMS analyzes scan results through AI/ML algorithms (Random Forest, Gradient Boosting) trained on 5M+ scans to detect fraud patterns including duplicate UIDs (same stamp scanned 100+ times), geographic anomalies (stamps scanned outside authorized territory), temporal patterns (scans before production date), and suspicious retailer behavior (unusual scanning volumes), generating real-time alerts to KRA enforcement officers with heatmap visualizations showing counterfeit concentration by county/sub-county for targeted market surveillance.

SeQR EMS retail scanners exceed all specifications:

a. Minimum scan speed: ≥3 scans per second (50% above requirement using high-performance Zebra TC52/Honeywell CT40 industrial scanners).

b. Offline capability: 72 hours local verification with 200K stamps cached in encrypted SQLite database, automatic sync every 5 minutes when WiFi/4G available, background queue for offline scans uploaded seamlessly.

c. Encryption standards: AES-256-GCM for stored stamp data with HSM-derived keys rotated quarterly; TLS 1.3 mandatory for all API communication with certificate pinning preventing man-in-the-middle attacks.

d. Battery life: ≥10 hours continuous operation (Samsung 5000mAh batteries, power-saving mode extending to 14 hours, USB-C fast charging 0-80% in 90 minutes).

e. Durability: IP54 rating standard (dust ingress protection, water splash resistant from all directions), ruggedized cases, Gorilla Glass screens, MIL-STD-810G drop tested 1.5m onto concrete.

f. Connectivity: 4G/LTE (supports Safaricom/Airtel/Telkom Kenya bands 3/7/20/28/38) + WiFi 5 (802.11ac dual-band 2.4/5GHz) + Bluetooth 5.0 (pair with UV/IR scanners, printers, wireless headsets).

g. Screen size: 6-inch HD+ display (1440x720 resolution, 500 nits brightness outdoor-readable, Corning Gorilla Glass, capacitive multi-touch).

h. Operating system: Android 12+ (Zebra/Honeywell enterprise-grade devices with 5-year security update commitment, AOSP hardened build with KRA MDM enrollment, remote wipe capability).

SeQR EMS retail scanners exceed all specifications:

a. Minimum scan speed: ≥3 scans per second (50% above requirement using high-performance Zebra TC52/Honeywell CT40 industrial scanners).

b. Offline capability: 72 hours local verification with 200K stamps cached in encrypted SQLite database, automatic sync every 5 minutes when WiFi/4G available, background queue for offline scans uploaded seamlessly.

c. Encryption standards: AES-256-GCM for stored stamp data with HSM-derived keys rotated quarterly; TLS 1.3 mandatory for all API communication with certificate pinning preventing man-in-the-middle attacks.

d. Battery life: ≥10 hours continuous operation (Samsung 5000mAh batteries, power-saving mode extending to 14 hours, USB-C fast charging 0-80% in 90 minutes).

e. Durability: IP54 rating standard (dust ingress protection, water splash resistant from all directions), ruggedized cases, Gorilla Glass screens, MIL-STD-810G drop tested 1.5m onto concrete.

f. Connectivity: 4G/LTE (supports Safaricom/Airtel/Telkom Kenya bands 3/7/20/28/38) + WiFi 5 (802.11ac dual-band 2.4/5GHz) + Bluetooth 5.0 (pair with UV/IR scanners, printers, wireless headsets).

g. Screen size: 6-inch HD+ display (1440x720 resolution, 500 nits brightness outdoor-readable, Corning Gorilla Glass, capacitive multi-touch).

h. Operating system: Android 12+ (Zebra/Honeywell enterprise-grade devices with 5-year security update commitment, AOSP hardened build with KRA MDM enrollment, remote wipe capability).

SeQR EMS mobile apps support all requirements:

a. Offline verification capability: Consumer app caches 200K stamp UIDs locally (24-72 hour buffer), Enforcement app caches 500K stamps with 7-day case data (operates fully offline for remote field operations), background sync every 5 minutes when connectivity restored, conflict resolution using last-write-wins with server timestamp authority.

b. Encrypted local cache: SQLite database encrypted using SQLCipher with AES-256-CBC, encryption keys derived from device secure element (iOS Keychain/Android KeyStore), automatic cache purge after 30 days inactivity or manual clear option in settings.

c. Multi-language support: English (default) and Swahili (Kiswahili) with real-time language switching, RTL text support for potential future Arabic, locale-aware date/time/currency formatting, translated UI labels and help content (100% translation coverage verified by native speakers).

d. Accessibility features: WCAG 2.1 AA compliant (screen reader compatible with Android TalkBack and iOS VoiceOver, semantic HTML labels, ARIA attributes), adjustable font sizes 100%-200% (settings persist per user), high contrast mode (color contrast ≥4.5:1), voice input for search fields using device microphone, haptic feedback for button presses, reduced motion option for users with vestibular disorders.

SeQR EMS mobile apps support all requirements:

a. Offline verification capability: Consumer app caches 200K stamp UIDs locally (24-72 hour buffer), Enforcement app caches 500K stamps with 7-day case data (operates fully offline for remote field operations), background sync every 5 minutes when connectivity restored, conflict resolution using last-write-wins with server timestamp authority.

b. Encrypted local cache: SQLite database encrypted using SQLCipher with AES-256-CBC, encryption keys derived from device secure element (iOS Keychain/Android KeyStore), automatic cache purge after 30 days inactivity or manual clear option in settings.

c. Multi-language support: English (default) and Swahili (Kiswahili) with real-time language switching, RTL text support for potential future Arabic, locale-aware date/time/currency formatting, translated UI labels and help content (100% translation coverage verified by native speakers).

d. Accessibility features: WCAG 2.1 AA compliant (screen reader compatible with Android TalkBack and iOS VoiceOver, semantic HTML labels, ARIA attributes), adjustable font sizes 100%-200% (settings persist per user), high contrast mode (color contrast ≥4.5:1), voice input for search fields using device microphone, haptic feedback for button presses, reduced motion option for users with vestibular disorders.

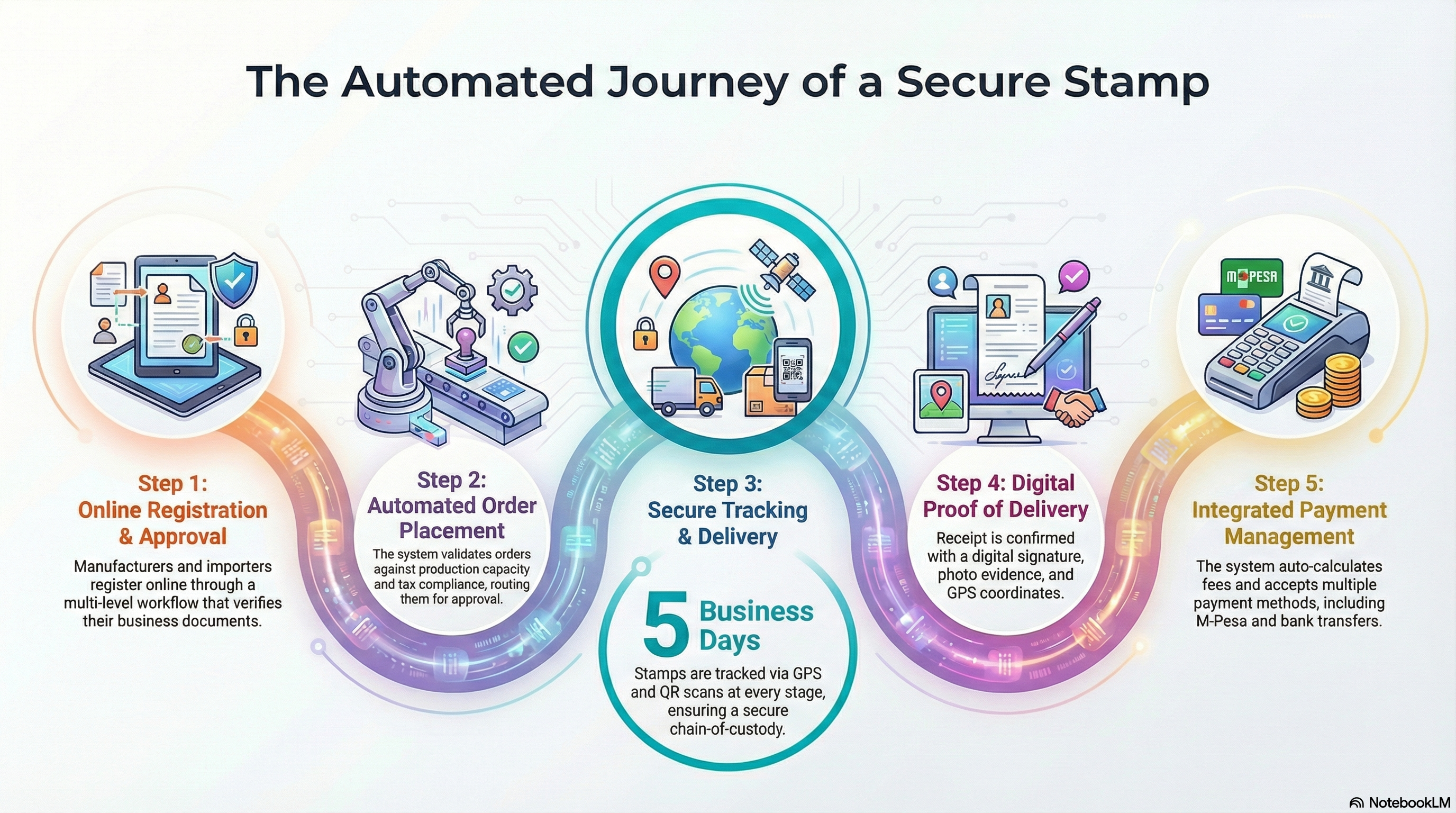

SeQR EMS provides automated approval process with online registration for manufacturers/importers/distributors (KRA PIN validation, business document verification, multi-level approval workflow from field officer to Commissioner), product and facility registration (SKU details, production capacity, GPS coordinates), and comprehensive audit trail of all registration actions with automated email/SMS notifications at each approval stage.

SeQR EMS provides automated approval process with online registration for manufacturers/importers/distributors (KRA PIN validation, business document verification, multi-level approval workflow from field officer to Commissioner), product and facility registration (SKU details, production capacity, GPS coordinates), and comprehensive audit trail of all registration actions with automated email/SMS notifications at each approval stage.

SeQR EMS provides automated ordering with multi-level approvals (manufacturer selects product/quantity, system validates against capacity, auto-approves if tax-compliant or routes to KRA field officer/supervisor/manager based on value/risk), automated stamp generation (laser engraving, QR encoding, quality verification in batches of 1,000/10 minutes), and automated distribution (dispatch to nearest issuance center, GPS-tracked courier delivery, digital proof-of-delivery with photo/signature, order-to-delivery within 5 business days standard or 2 days express).

SeQR EMS tracks paper stamps from production to delivery with batch-level tracking (unique Batch ID, QR scanning at personalization/quality-control/packaging/warehouse/dispatch stages), warehouse inventory management (5 issuance centers with real-time FIFO stock rotation, biometric vault access, daily reconciliation), GPS-enabled transportation (location ping every 5 minutes, geofenced route compliance ±500m, tamper-evident sealed containers), and digital proof-of-delivery (signature on tablet, photo evidence, GPS coordinates, automatic inventory transfer from KRA to manufacturer account with complete chain-of-custody audit trail for 5-year retention).

SeQR EMS provides automated payment management with auto-calculated fees (KRA-approved rates per category plus quantity discounts and delivery charges), multiple payment methods (M-Pesa instant confirmation via Daraja API, bank cards via Pesapal/iPay, bank transfer with auto-reconciliation, Airtel Money/T-Kash), real-time payment tracking (Pending→Processing→Confirmed→Failed with reasons), auto-generated PDF receipts, outstanding dues tracking with automatic reminders (7 days before due, on due date, 3/7 days overdue), account suspension if >30 days overdue, and daily automated reconciliation with iTax integration for excise duty cross-reference.

SeQR EMS records all deliveries capturing WHO FCTC Article 8.4.1 mandatory data points:

SeQR EMS records all deliveries capturing WHO FCTC Article 8.4.1 mandatory data points:

(a) date/location of manufacture,

(b) facility details,

(c) machine/line ID,

(d) production shift/time,

(e) first customer details with TIN/PIN,

(f) intended retail market county/sub-county,

(g) product description (brand, SKU, pack type, quantity),

(h) warehousing/shipping/transport mode/vehicle/driver,

(i) subsequent purchaser identity,

(j) shipment route/date/destination/departure point/consignee, with sealed digital manifest (QR code, ECDSA-256 signature, tamper detection), real-time GPS tracking (30-second pings for high-value shipments), route compliance monitoring (geofenced ±500m tolerance), and delivery confirmation via mobile app with photo/signature/GPS/timestamp automatically updating delivery status and notifying manufacturer and KRA.

SeQR EMS provides ML-based revenue forecasting (ARIMA, Prophet, LSTM models trained on 3+ years historical data achieving 85-90% accuracy with confidence intervals), production trend analysis (daily/weekly/monthly patterns, seasonal peaks, anomaly detection for sudden drops/spikes), compliance impact simulations (projected revenue gain from reducing counterfeiting from 15% to 5%), market share analysis per manufacturer (track changes over time, competitive dynamics), and interactive "what-if" calculator for policy makers (adjust tax rates, stamp fees, compliance rates to see projected impact on revenue, consumption, employment, illicit trade with sensitivity analysis and optimization recommendations).

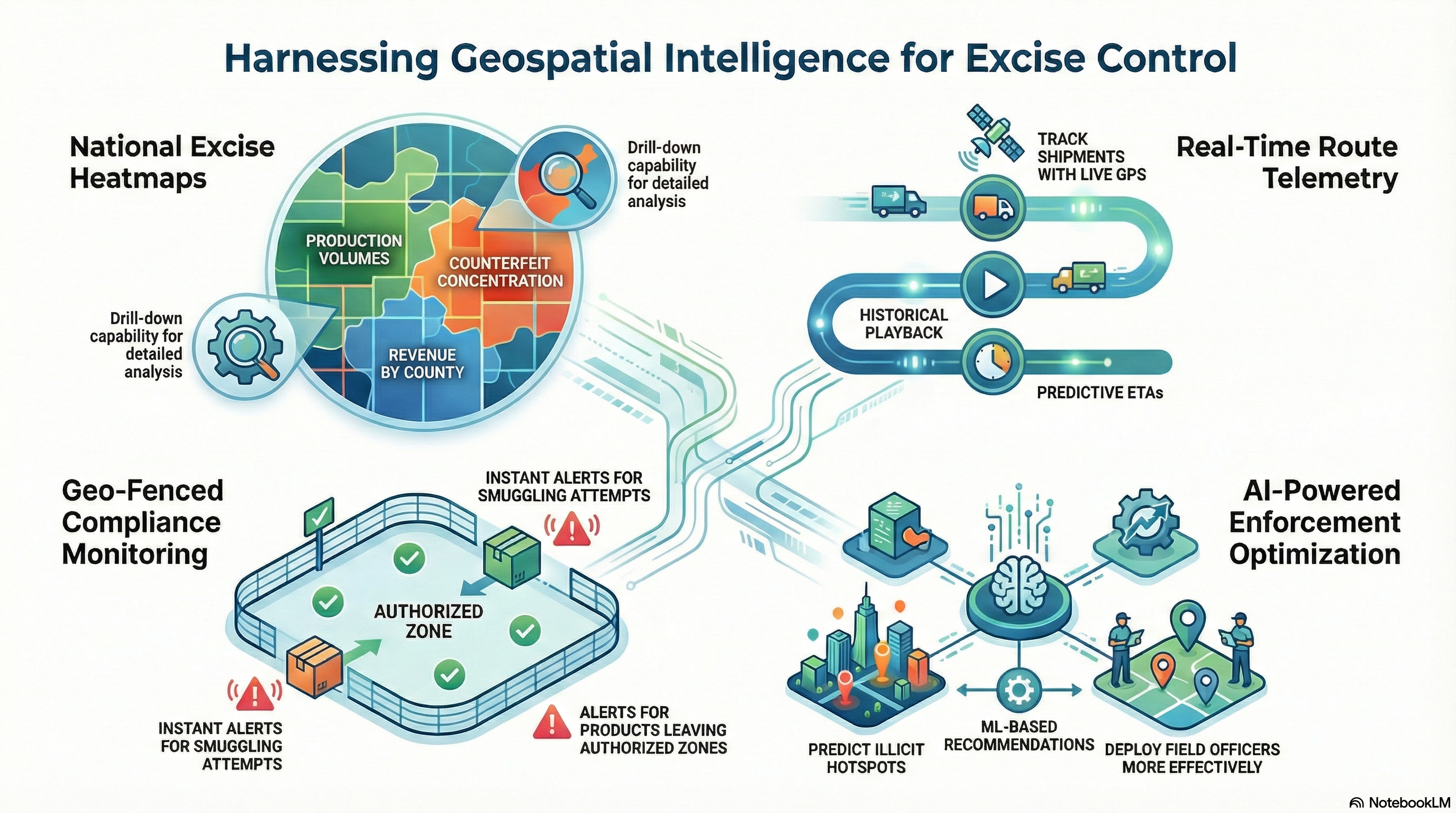

SeQR EMS provides national excise heatmaps (production volumes, counterfeit concentration, revenue collection, compliance rates by county/sub-county with drill-down capability and time-lapse animation), real-time route-movement telemetry (GPS tracking every 30 seconds for high-risk routes/5 minutes standard with historical playback, speed analysis, ETA prediction), geo-fenced compliance (authorized zones per manufacturer/product with real-time alerts if products leave permitted territory, border zone monitoring 50km buffer for smuggling detection), and enforcement optimization (ML-based predictive hotspot mapping, resource allocation recommendations, field officer tracking with nearest-officer dispatch for counterfeit incidents).

SeQR EMS provides national excise heatmaps (production volumes, counterfeit concentration, revenue collection, compliance rates by county/sub-county with drill-down capability and time-lapse animation), real-time route-movement telemetry (GPS tracking every 30 seconds for high-risk routes/5 minutes standard with historical playback, speed analysis, ETA prediction), geo-fenced compliance (authorized zones per manufacturer/product with real-time alerts if products leave permitted territory, border zone monitoring 50km buffer for smuggling detection), and enforcement optimization (ML-based predictive hotspot mapping, resource allocation recommendations, field officer tracking with nearest-officer dispatch for counterfeit incidents).

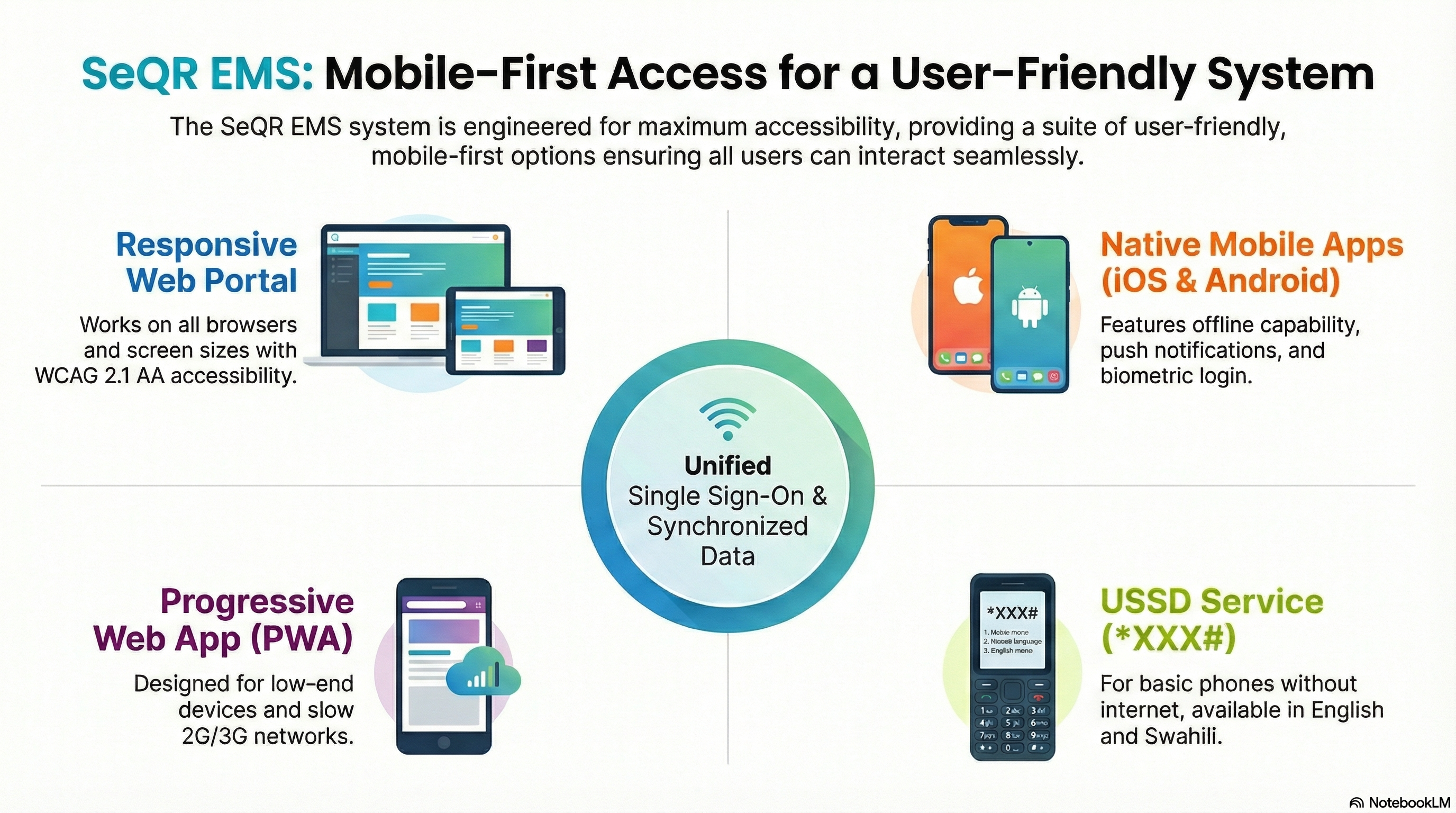

SeQR EMS provides user-friendly mobile-first access through responsive web portal (works on all browsers/screen sizes with intuitive navigation, role-based dashboards, WCAG 2.1 AA accessibility compliant), native mobile apps for Android 8.0+ and iOS 13+ (offline capability, push notifications, biometric login, camera/GPS integration), Progressive Web App for mobile web browsers (works on low-end devices with 512MB RAM and 2G/3G networks, installable on home screen, data savings mode), and USSD *XXX# for basic phones (menu-driven interface in English/Swahili, stamp verification/counterfeit reporting/order status, works on any phone without internet), all with unified single sign-on and synchronized data across channels.

SeQR EMS provides user-friendly mobile-first access through responsive web portal (works on all browsers/screen sizes with intuitive navigation, role-based dashboards, WCAG 2.1 AA accessibility compliant), native mobile apps for Android 8.0+ and iOS 13+ (offline capability, push notifications, biometric login, camera/GPS integration), Progressive Web App for mobile web browsers (works on low-end devices with 512MB RAM and 2G/3G networks, installable on home screen, data savings mode), and USSD *XXX# for basic phones (menu-driven interface in English/Swahili, stamp verification/counterfeit reporting/order status, works on any phone without internet), all with unified single sign-on and synchronized data across channels.

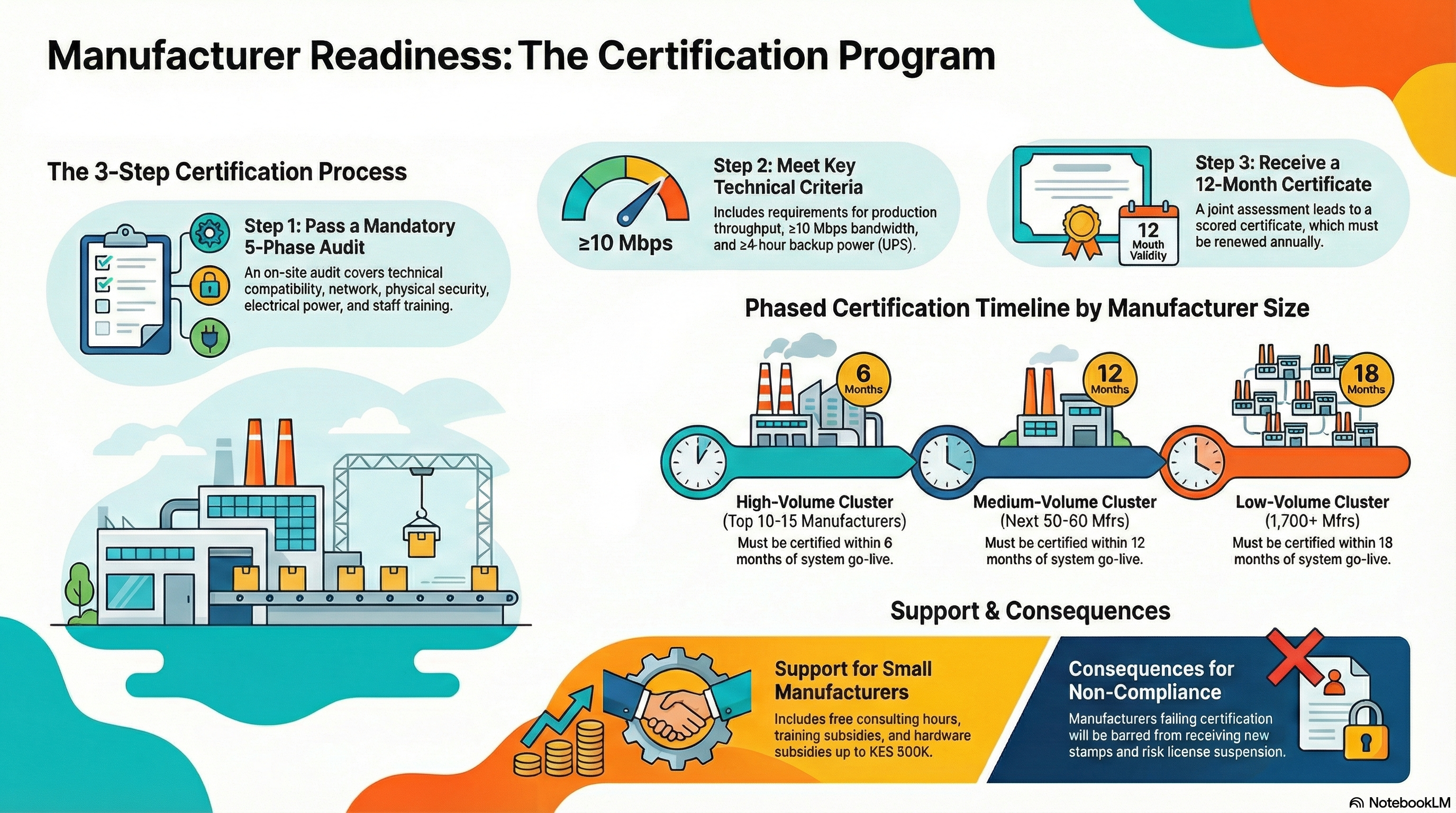

SeQR EMS implements comprehensive manufacturer readiness certification:

a. Pre-Integration Audit: Mandatory 5-phase audit conducted by Devharsh engineers before manufacturer integration (Phase 1 Technical Compatibility: assess PLC brand/firmware versions/protocols supported determining OPC-UA/Modbus/custom adapter needed, Phase 2 Network Infrastructure: test bandwidth ≥10 Mbps sustained using iPerf tool, latency <50ms ping to KRA cloud, packet loss <1%, firewall rules allowing VPN ports UDP 1194/4500, Phase 3 Physical Security: verify CCTV coverage production floor/storage areas, secure cage for edge servers with padlock/biometric access, stamp storage vault fireproof rating 1-hour minimum, Phase 4 Electrical Infrastructure: backup power UPS for edge server + critical equipment covering ≥4 hours average outage duration in Kenya, generator backup for production line allowing continued operation during grid failures common in some regions, Phase 5 Staff Training: identify 2-3 technical staff for intensive training, assess English proficiency for communicating with Devharsh support, verify at least 1 staff has basic IT skills networking/database concepts), audit report documents findings (graded red/yellow/green per criterion, red = critical showstopper must fix, yellow = improvement recommended but workaround possible, green = meets requirements), remediation plan created if audit identifies gaps (manufacturer provided 30-60 day timeline to address red items with Devharsh guidance, re-audit after remediation, yellow items addressed during pilot phase).

b. Certification Criteria: Minimum production throughput (small manufacturers <10K units/day exempt, medium 10-50K units/day requires ≥5K sustained throughput measured over 8-hour shift, high >50K units/day requires ≥25K throughput, stress test simulates 110% rated capacity validating equipment can handle peak demand without breakdown), network bandwidth (≥10 Mbps dedicated symmetrical bandwidth tested using speedtest.net + iPerf, fiber optic preferred but 4G LTE acceptable backup if primary ISP fails, dual ISP redundancy required for Tier 1 manufacturers critical to tax revenue, latency <100ms to KRA cloud Nairobi, packet loss <1% measured over 72-hour continuous monitoring), backup power (UPS Uninterruptible Power Supply minimum 4-hour runtime for edge server + OPC counter + networking equipment, tested monthly with logs submitted to KRA, automatic failover <5 seconds preventing data loss during power cut common in Kenya, generator backup for production line 24-hour fuel capacity ensuring continued operations during prolonged outages, diesel/petrol generator serviced quarterly with maintenance log), trained technical staff (minimum 2 staff trained on EGMS system operation, 1 staff trained on edge server administration, all staff English proficient for reading manuals/communicating with Devharsh support, staff names registered in EGMS so KRA knows who to contact for technical issues, annual refresher training required as system evolves), physical security (production floor secured with access control biometric or card, CCTV cameras covering all entry/exit points + production lines with 30-day recording retention, edge server housed in locked cage/room temperature-controlled preventing overheating, stamp storage vault fireproof + burglar-resistant with dual-key access manufacturing manager + accountant reducing theft risk).

c. Certification Process: Joint assessment (Devharsh engineer + KRA licensing officer + manufacturer technical manager conduct on-site audit together, Devharsh assesses technical readiness, KRA assesses compliance history + financial stability, manufacturer provides honest disclosure of challenges), certification scoring (100-point scorecard: technical compatibility 30 points, network infrastructure 20 points, physical security 15 points, electrical infrastructure 15 points, staff training 10 points, compliance history 10 points, pass threshold ≥70 points), certificate issuance (pass: manufacturer receives certification PDF/printed certificate signed by Devharsh + KRA, valid 12 months from issue date, displayed at facility for audits, fail: manufacturer receives rejection letter with specific gaps to address + recommended remediation timeline + support resources available), recertification requirement (certificates expire 12 months, manufacturer must recertify annually, recertification simpler than initial = remote audit + documentation review unless major equipment changes, automatic renewal for Tier 1 manufacturers with 95%+ compliance score past year).

d. Support for Small Manufacturers: Technical assistance (Devharsh provides up to 40 hours FREE consulting for manufacturers with <100M KES annual revenue to achieve certification, services include: network assessment + recommendations for ISP/equipment purchases, PLC firmware upgrade guidance, electrical infrastructure design for backup power, physical security audit + recommendations for CCTV/access control, staff training needs analysis + curriculum design), training subsidies (up to 16 hours FREE training for small manufacturer staff, courses: EGMS portal navigation, production reporting, troubleshooting common issues, edge server basics if managing internally, Swahili-language training materials for staff with limited English), hardware subsidies (up to KES 500K subsidy for essential equipment, eligible items: edge server industrial PC KES 200K, UPS 4-hour capacity KES 100K, 4G LTE router backup internet KES 20K, CCTV cameras 4-camera kit KES 80K, network cabling Cat6 per meter KES 100K allocation, subsidy paid directly to approved suppliers preventing cash diversion), application process (manufacturer applies via EGMS portal uploading financial statements proving <100M revenue, KRA approves within 7 days, Devharsh contacted to schedule assessment, subsidy approved per assessment report showing genuine need + will achieve certification with support).

e. Vendor Support Obligations (Low-Capacity Manufacturers): 100M KES revenue threshold (manufacturers below this receive FREE support as described in

SeQR EMS implements comprehensive manufacturer readiness certification:

a. Pre-Integration Audit: Mandatory 5-phase audit conducted by Devharsh engineers before manufacturer integration (Phase 1 Technical Compatibility: assess PLC brand/firmware versions/protocols supported determining OPC-UA/Modbus/custom adapter needed, Phase 2 Network Infrastructure: test bandwidth ≥10 Mbps sustained using iPerf tool, latency <50ms ping to KRA cloud, packet loss <1%, firewall rules allowing VPN ports UDP 1194/4500, Phase 3 Physical Security: verify CCTV coverage production floor/storage areas, secure cage for edge servers with padlock/biometric access, stamp storage vault fireproof rating 1-hour minimum, Phase 4 Electrical Infrastructure: backup power UPS for edge server + critical equipment covering ≥4 hours average outage duration in Kenya, generator backup for production line allowing continued operation during grid failures common in some regions, Phase 5 Staff Training: identify 2-3 technical staff for intensive training, assess English proficiency for communicating with Devharsh support, verify at least 1 staff has basic IT skills networking/database concepts), audit report documents findings (graded red/yellow/green per criterion, red = critical showstopper must fix, yellow = improvement recommended but workaround possible, green = meets requirements), remediation plan created if audit identifies gaps (manufacturer provided 30-60 day timeline to address red items with Devharsh guidance, re-audit after remediation, yellow items addressed during pilot phase).

b. Certification Criteria: Minimum production throughput (small manufacturers <10K units/day exempt, medium 10-50K units/day requires ≥5K sustained throughput measured over 8-hour shift, high >50K units/day requires ≥25K throughput, stress test simulates 110% rated capacity validating equipment can handle peak demand without breakdown), network bandwidth (≥10 Mbps dedicated symmetrical bandwidth tested using speedtest.net + iPerf, fiber optic preferred but 4G LTE acceptable backup if primary ISP fails, dual ISP redundancy required for Tier 1 manufacturers critical to tax revenue, latency <100ms to KRA cloud Nairobi, packet loss <1% measured over 72-hour continuous monitoring), backup power (UPS Uninterruptible Power Supply minimum 4-hour runtime for edge server + OPC counter + networking equipment, tested monthly with logs submitted to KRA, automatic failover <5 seconds preventing data loss during power cut common in Kenya, generator backup for production line 24-hour fuel capacity ensuring continued operations during prolonged outages, diesel/petrol generator serviced quarterly with maintenance log), trained technical staff (minimum 2 staff trained on EGMS system operation, 1 staff trained on edge server administration, all staff English proficient for reading manuals/communicating with Devharsh support, staff names registered in EGMS so KRA knows who to contact for technical issues, annual refresher training required as system evolves), physical security (production floor secured with access control biometric or card, CCTV cameras covering all entry/exit points + production lines with 30-day recording retention, edge server housed in locked cage/room temperature-controlled preventing overheating, stamp storage vault fireproof + burglar-resistant with dual-key access manufacturing manager + accountant reducing theft risk).

c. Certification Process: Joint assessment (Devharsh engineer + KRA licensing officer + manufacturer technical manager conduct on-site audit together, Devharsh assesses technical readiness, KRA assesses compliance history + financial stability, manufacturer provides honest disclosure of challenges), certification scoring (100-point scorecard: technical compatibility 30 points, network infrastructure 20 points, physical security 15 points, electrical infrastructure 15 points, staff training 10 points, compliance history 10 points, pass threshold ≥70 points), certificate issuance (pass: manufacturer receives certification PDF/printed certificate signed by Devharsh + KRA, valid 12 months from issue date, displayed at facility for audits, fail: manufacturer receives rejection letter with specific gaps to address + recommended remediation timeline + support resources available), recertification requirement (certificates expire 12 months, manufacturer must recertify annually, recertification simpler than initial = remote audit + documentation review unless major equipment changes, automatic renewal for Tier 1 manufacturers with 95%+ compliance score past year).

d. Support for Small Manufacturers: Technical assistance (Devharsh provides up to 40 hours FREE consulting for manufacturers with <100M KES annual revenue to achieve certification, services include: network assessment + recommendations for ISP/equipment purchases, PLC firmware upgrade guidance, electrical infrastructure design for backup power, physical security audit + recommendations for CCTV/access control, staff training needs analysis + curriculum design), training subsidies (up to 16 hours FREE training for small manufacturer staff, courses: EGMS portal navigation, production reporting, troubleshooting common issues, edge server basics if managing internally, Swahili-language training materials for staff with limited English), hardware subsidies (up to KES 500K subsidy for essential equipment, eligible items: edge server industrial PC KES 200K, UPS 4-hour capacity KES 100K, 4G LTE router backup internet KES 20K, CCTV cameras 4-camera kit KES 80K, network cabling Cat6 per meter KES 100K allocation, subsidy paid directly to approved suppliers preventing cash diversion), application process (manufacturer applies via EGMS portal uploading financial statements proving <100M revenue, KRA approves within 7 days, Devharsh contacted to schedule assessment, subsidy approved per assessment report showing genuine need + will achieve certification with support).

e. Vendor Support Obligations (Low-Capacity Manufacturers): 100M KES revenue threshold (manufacturers below this receive FREE support as described in

(d) above, verified through KRA tax returns or audited financial statements preventing gaming the system), 100-500M KES range (50% subsidy on equipment + 50% discount on consulting hours, e.g., KES 500K equipment subsidy becomes KES 250K, 40 hours consulting at normal rate KES 10K/hour = KES 400K becomes KES 200K), subsidy caps (total FREE support per manufacturer capped at KES 500K prevents abuse, if manufacturer needs more equipment, pays difference, e.g., KES 700K equipment needed = KES 500K subsidy + KES 200K manufacturer pays), support duration (subsidies available during first 18-month rollout period only, after 18 months manufacturers expected to be self-sufficient or pay commercial rates for additional support), vendor penalty if insufficient support (if Devharsh fails to provide promised FREE support resulting in manufacturer unable to certify, KRA can penalize Devharsh KES 2-5M per incident, prevents vendor cost-cutting at expense of small manufacturers critical to inclusive rollout).

f. Manufacturer Certification Timeline & Clustering: High-volume cluster (manufacturers producing >1B stamps/year = top 10-15 manufacturers representing 60% stamp volume, must certify within 6 months of EGMS go-live Month 1-6, prioritized because delay impacts 60% tax revenue, Devharsh dedicates senior engineers to this cluster ensuring success), medium-volume cluster (manufacturers producing 100M-1B stamps/year = next 50-60 manufacturers representing 30% stamp volume, must certify within 12 months Month 7-12, slightly less urgent but still significant revenue contribution, standard Devharsh support team handles), low-volume cluster (manufacturers producing <100M stamps/year = remaining 1,700+ manufacturers representing 10% stamp volume, must certify within 18 months Month 13-24, longest timeline given small individual impact + likely to need most technical assistance due to limited IT resources, Devharsh on-site coordinators in Kenya travel to facilities providing hands-on support), certification tracking dashboard (KRA views real-time progress: high-volume 12/15 certified 80% on track, medium-volume 35/60 certified 58% slightly behind, low-volume 420/1,700 certified 25% early stage, drill-down to individual manufacturers showing certification stage: not started/audit scheduled/gaps identified/remediation in progress/recertification passed).

g. Consequences for Failures: Non-certified manufacturers barred (manufacturers failing certification by deadline SHALL NOT be issued new stamps, existing stamp inventory used up but no reorders, production must cease once stamps exhausted unless certification achieved), production suspension power (KRA Excise Act empowers Commissioner to suspend manufacturer license for non-compliance, legal precedent established in Kenyan courts upholding suspension, appeals process available but suspension remains during appeal unless court orders injunction), vendor penalties progressive (if Devharsh fails to certify ≥70% of high-volume cluster by Month 6, penalty KES 2M + KES 50K per day delay, if fails to certify ≥70% medium-volume by Month 12, penalty KES 5M + KES 100K per day delay, if fails to certify ≥70% low-volume by Month 18, penalty KES 10M + KES 200K per day delay escalating to incentivize performance), penalty escrow (10% of Devharsh contract value held in escrow by KRA, released upon successful certification milestones achieved, if milestones missed penalties deducted from escrow before release, protects KRA from vendor non-performance), force majeure exceptions (if delays due to circumstances beyond Devharsh control e.g., manufacturer bankruptcy, factory fire, government-imposed lockdown, Kenya political instability, penalties waived upon documented proof, timelines extended by delay duration).

h. Mandatory Integration Timeline: Post-certification integration (once manufacturer certified, integration must complete within SLA or face consequences, SLA varies by manufacturer tier balancing urgency vs. complexity), high-volume manufacturers (30-day integration SLA, countdown starts day after certification issued, Devharsh dedicates team ensuring edge server installed, OPC/MVS integrated, test data transmitted to cloud, user training completed, go-live sign-off by manufacturer + KRA within 30 days, if missed penalty KES 50K per day delay capped at KES 1.5M), medium-volume manufacturers (60-day integration SLA, more relaxed timeline acknowledges smaller manufacturer IT teams may need longer to adapt, penalty KES 25K per day delay capped at KES 1M), low-volume manufacturers (90-day integration SLA, longest timeline given likely to have minimal IT resources + Devharsh providing extensive hand-holding, penalty KES 10K per day delay capped at KES 500K), integration tracking (dashboard shows per-manufacturer status: certified awaiting integration start, integration in progress % complete, integration testing, go-live completed, overdue flagged in red with days past SLA + penalty accrued KES amount).

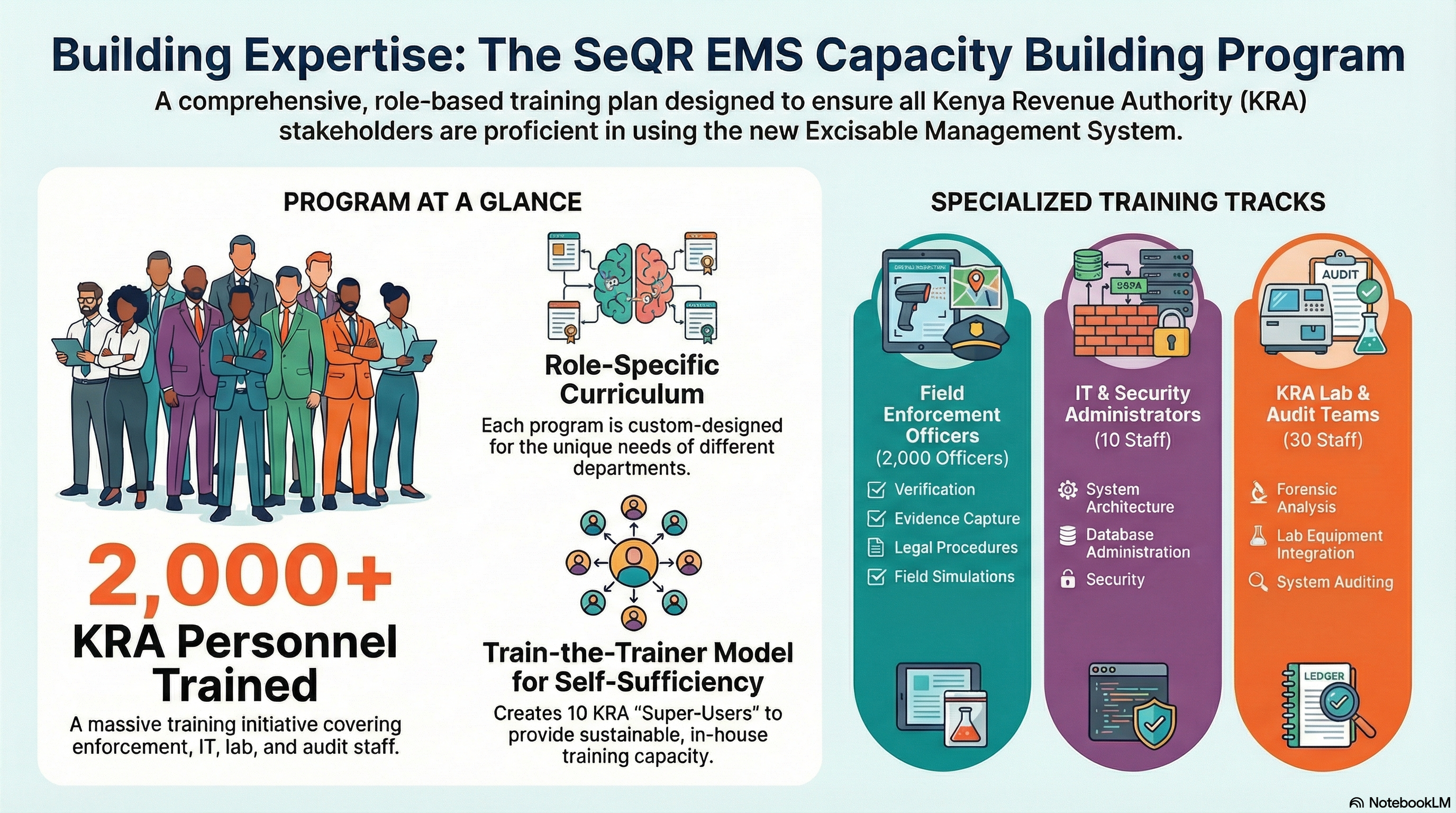

SeQR EMS training includes functional training for 200+ KRA users (2-day instructor-led covering system features, manufacturer management, enforcement workflows, reporting with user manuals, video tutorials, hands-on practice, 70% pass score required) and technical training for 10-15 KRA IT staff (5-day intensive covering system architecture, database administration, DevOps, security management, troubleshooting with 150+ page admin guide, video recordings, 3-month post-training helpline), delivered on-site at KRA headquarters and regional offices by Devharsh certified trainers following train-the-trainer model to build internal KRA capacity with quarterly refresher webinars and annual advanced training sessions. b) Detailed Functional and Technical Training Plan:

i. Field Enforcement Officers Training (5-Day Program for 2,000 officers in batches of 50):

- Day 1 - System Introduction: EGMS overview mission/objectives (2 hours lecture), enforcement app installation Android/iOS from Play/App Store (1 hour hands-on), account registration biometric enrollment fingerprint/Face ID (1 hour practice), portal navigation dashboard/menu structure (2 hours walkthrough), basic stamp verification QR scanning product (2 hours practice with sample stamps).

- Day 2 - Verification Techniques: Multi-spectral scanning UV/IR/NFC using handheld devices (3 hours hands-on with Lighthouse scanners), overt feature inspection hologram/color-shift/microtext using magnifying glass (2 hours practice), guided verification workflow app prompts officer through checklist (2 hours practice), result interpretation Valid/Invalid/Suspicious/Counterfeit with actions required (1 hour discussion).

- Day 3 - Evidence Capture: High-resolution photography multiple angles closeup/context/hologram detail (2 hours practice), GPS coordinates automatic capture timestamp/location on each photo (1 hour demonstration), witness signatures digital signature capture on tablet from store owner/manager (1 hour practice), chain-of-custody documentation evidence bag sealing + QR code linking physical evidence to digital case (2 hours hands-on), case management workflow create case/classify violation/assign severity/upload evidence/multi-agency referral (2 hours practice).

- Day 4 - Advanced Features + Field Simulations: Offline operation 72-hour capability cache management background sync (1 hour demonstration), batch verification scanning 50 products in rapid succession generating batch report (1 hour practice), seizure procedures inventory seized goods/generate seizure receipt/secure storage pending investigation (2 hours walkthrough), legal documentation generation case summary report for prosecutor with evidence photos/witness statements (2 hours practice), field simulation role-playing raid on fake market stall with actors playing vendors/customers, officer practices full workflow from verification to seizure to documentation (2 hours scenario).

- Day 5 - Legal Procedures + Certification Exam: Court-admissible evidence requirements chain-of-custody integrity/timestamps/GPS coordinates (1 hour lecture), testimony preparation using EGMS evidence package organizing chronological timeline for court (1 hour lecture), prosecution workflow integration KRA enforcement → NPS criminal investigation → ODPP prosecution → court case management (1 hour lecture), Q&A session open forum for officers to ask questions/clarifications (1 hour discussion), practical field test each officer conducts mock enforcement operation scanned products/captured evidence/created case, assessed by trainer on 10-point checklist (2 hours practical exam), certification ceremony pass 80%+ score receive certificate + badge printed/digital, authorized to use EGMS in real operations (1 hour closing).

ii. KRA Lab Officers Training (3-Day Program for 20 officers):

- Day 1 - Lab Equipment Integration: EGMS lab module overview (2 hours), integrating lab equipment UV/IR/XRF spectrometers via USB/Bluetooth (2 hours hands-on setup), stamp forensic analysis workflow receive seized sample from enforcement → assign lab case number → perform tests UV reactivity/IR markers/chemical composition → document findings photos/test data → upload to EGMS → generate lab report (3 hours walkthrough + practice).

- Day 2 - Advanced Verification Techniques: Covert feature testing anti-Stokes phosphors using 980nm laser + spectrometer reading emission wavelengths comparing to authentic sample reference library (3 hours hands-on), substrate taggant detection XRF scanning detecting nanoparticle signatures comparing to KRA-approved suppliers fingerprints (2 hours hands-on), digital signature verification extracting UID from stamp → querying EGMS API for public key → verifying ECDSA signature → result genuine/forged (2 hours demonstration + practice).

- Day 3 - Reporting + Quality Control: Lab report generation template with findings/test data/photos/conclusion genuine vs. counterfeit (2 hours practice), quality control procedures calibration schedules/reference sample management/blind testing for accuracy (2 hours lecture), court expert testimony preparing lab reports admissible in court/testifying as expert witness basics (2 hours lecture), Q&A + certification exam 20 multiple choice questions on equipment/procedures, practical test: analyze unknown sample determining authenticity, 80%+ pass score (2 hours exam + closing).

iii. Security, System, and Database Administrators Training (5-Day Intensive Bootcamp for 10 IT staff):

- Day 1 - System Architecture: Microservices architecture overview 12 services/API gateway/service mesh (2 hours lecture + architecture diagram walkthrough), technology stack Spring Boot/React/Flutter/PostgreSQL/MongoDB/Redis/Kafka (1 hour), cloud infrastructure AWS/Azure Kubernetes clusters/load balancers/databases (2 hours), networking VPN tunnels manufacturer edge servers to KRA cloud/firewall rules/DMZ zones (2 hours), security architecture zero-trust model/HSM integration/encryption at rest and in transit (1 hour).

- Day 2 - Database Administration: PostgreSQL deep-dive schema design/indexing strategies/query optimization (3 hours), hands-on lab slow query identification using pg_stat_statements → adding indexes → EXPLAIN ANALYZE comparing before/after (2 hours), backup and restore procedures daily automated backups/manual on-demand backups/point-in-time recovery PITR (2 hours), replication setup master-slave replication/read replicas for reporting queries offloading production database (1 hour).

- Day 3 - DevOps and Monitoring: CI/CD pipeline GitLab CI/GitHub Actions automated build-test-deploy (2 hours), deployment procedures Kubernetes rolling updates/blue-green deployments/canary releases/rollback if errors (2 hours), monitoring dashboards Prometheus metrics/Grafana visualizations/alert configuration (2 hours), log analysis ELK Stack searching logs/identifying errors/correlating events across microservices (2 hours).

- Day 4 - Security Management: HSM operations Thales Luna key generation ceremony/key rotation quarterly/backup procedures (2 hours), encryption key management lifecycle generation/storage/rotation/archival/destruction (1 hour), SSL/TLS certificate management certificate renewal annual/wildcard vs. individual certificates/Let's Encrypt automation (1 hour), firewall rules auditing reviewing rules quarterly/removing unused rules/principle of least privilege (1 hour), security audit log review analyzing failed login attempts/unauthorized access/data export anomalies (2 hours), vulnerability scanning Snyk/SonarQube interpreting CVSS scores/prioritizing remediation/patching timelines (1 hour).

- Day 5 - Troubleshooting + Disaster Recovery: Common issues and resolutions application crashes/database connection exhaustion/slow queries/certificate expiration (2 hours), log file interpretation reading stack traces/identifying root cause/correlating logs across services (2 hours), debug mode enabling debug logging/analyzing verbose logs/disabling after troubleshooting (1 hour), disaster recovery drills simulating Nairobi site failure/activating Mombasa DR site/failover procedures/RTO 4 hours target (2 hours), escalation to Devharsh when to escalate/how to provide diagnostics/SLA expectations (1 hour), certification exam 30 multiple choice + 2 practical scenarios troubleshooting simulated issues, 75%+ pass score (2 hours exam + closing ceremony).

iv. System Auditors Training (2-Day Program for 10 auditors):

- Day 1 - Audit Trail and Compliance: Audit trail overview what's logged/where stored/retention period 5 years (1 hour), accessing audit logs via EGMS admin portal/database queries/exported reports (2 hours hands-on), searching and filtering logs by user/date range/action type/module (2 hours practice), interpreting audit records WHO did WHAT WHEN WHERE WHY BEFORE-AFTER values (2 hours with examples), regulatory compliance mapping audit trail to Kenya Data Protection Act 2019/ISO 27001/PCI DSS requirements (1 hour lecture).